Copy URL to Clipboard

Copy URL to Clipboard

As your business grows, so too will your logistics requirements. Once you get past just a few orders a day, it’s time to look into warehousing space and professional distribution. Generally, there are two ways of accomplishing this: purchasing a warehouse or storage facility along with delivery vehicles, or outsourcing logistics responsibilities to a third party logistics (3PL) provider.

Key Takeaways

In this article, we’ll look at self fulfillment vs outsourced logistics, and how Fulfillment and Distribution can help your business decide if 3PL fulfillment is the right choice for you.

Self fulfillment is pretty straightforward: when you receive an order, you pick it, package it, and arrange for delivery either via your own delivery vehicles or parcel mail. You control and execute the logistics processes of your business.

By contrast, a 3PL acts as a sort of outsourced logistics department. Depending on the level of service you sign up for, they could simply store your goods or set up fulfillment services and delivery on your behalf. They’re not part of your business, but their contribution to your success can be significant.

With those terms defined, we can move on to the most obvious question for shippers when it comes to this subject: should I hire a 3PL or build out warehousing and delivery in house?

Related: How to Choose a 3PL Warehouse Provider

To compare the expense and benefits of these two approaches, let’s assume you own a small business selling artisanal cooking oils. Until now, your place of residence has been able to serve as your office and warehouse, while daily mail dropoffs and some final-mile deliveries for local customers are sufficient to ensure that goods arrive on time.

Looking at your business’s growth projections, you can see that within two to three short months demand is going to increase to a level where you won’t be able to store goods or complete the volume of deliveries you receive on a daily basis. You’re going to need more storage and delivery options to keep your customers happy.

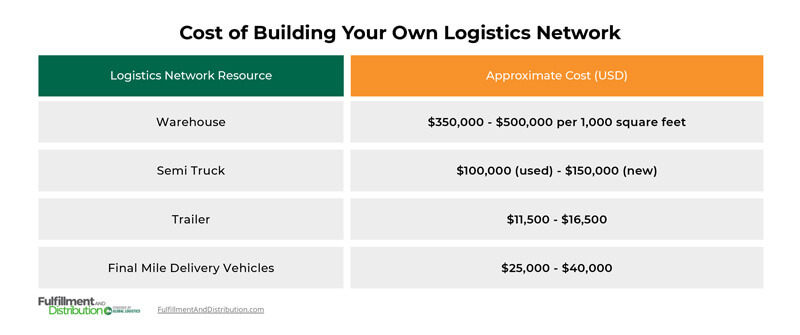

Considering the time and money you have likely invested in your business, it’s understandable that your first instinct would be to continue the DIY approach. These are some of the costs you can expect if you choose this option

Without even getting into ongoing costs like payroll, insurance, and truck upkeep, initial expenditures can easily crest $600,000 even if you find great deals. You’ll maintain full control of the logistics decision-making process, but not without a price.

On the other hand, a 3PL will not require this kind of money up front. With the resources and carrier relationships they have in place, you’d pay a fraction of what it would take to set up your own logistics, usually hundreds or thousands of dollars a month.

Depending on your needs, the 3PL will:

In most cases, you’ll find that 3PLs like us also offer a variety of accessorial services like kitting and reverse logistics. Given the option of a relatively low monthly bill vs a massive initial spend, many growing businesses take the 3PL route toward national distribution since the provider can easily scale services as needed while still giving business owners some say over the storage and delivery process.

The appeal of controlling every aspect of your business to its last detail is understandable. However, logistics is a business in and of itself, and it’s one where Fulfillment and Distribution excels. Partnering with us will make it easy to adjust processes as customer demands and product availability changes.

Are you ready to take the next step in growing your business? Call us at (866) 902-4262 or submit a contact form online today!