Copy URL to Clipboard

Copy URL to Clipboard

By taking advantage of kitting in warehousing, shippers can meet consumer demands, drive profits, and reduce overall business expenses. To make the most of kitting, it’s important to understand how it impacts warehousing and shipping.

Key Takeaways

In the guide below, we’ll take a look at the basics of warehouse kitting and the advantages it offers to businesses.

Table of Contents

When you build a kit, multiple related products with individual stock-keeping unit numbers (SKUs) are packaged together as single .

In practice, you can break kitting down into three steps:

This service is performed for a wide variety of industries including consumer electronics, auto parts, and even fresh food.

Consider these more specific examples of how kitting is used in warehousing:

Given that some goods could be applied to multiple overall kits, SKUs should be tracked separately for inventory and revenue purposes.

When discussing kitting, it’s important to remember the items included must be related to each other, which means they complement one another in some way. There are similar processes called bundling and assembly, but they differ from kitting in significant ways.

Before we get much further into kitting, let’s distinguish these three processes.

Now we can examine why businesses might choose to kit their goods and the benefits kitting can provide to everyone involved in the transaction.

Not every business will want (or need) to use a kitting service, so knowing when it’s useful is important. Below, I’ve listed some common reasons that businesses choose to kit their goods.

Sometimes, kitting reduces the costs of warehousing and shipping. Consider the following scenario.

An online retailer that sells office supplies notices that customers frequently purchase a pack of pens, a legal pad, and a padfolio together. By creating a kit of these items, the retailer can reduce pick and pack costs from their distribution partners.

Companies can also reduce shipping costs by using custom packaging that reduces the size and weight of the shipments compared to if they had been shipped individually.

Offering pre-built options for customers to choose from can put them in the driver’s seat of their purchase.

For instance, the video game company Nintendo offers pre-packaged console sets that include a game, controller, and all necessary cords. By offering multiple sets with different games, consumers feel empowered to choose the one that they like. This also spares the disappointment of receiving a console without a game to play immediately.

After analyzing sales data, a company might discover some related items aren’t selling well. This creates excess inventory. Kitting can sometimes solve this issue by increasing the value proposition of the items in question.

Let’s say a book company publishes a 10-volume children’s series, but two of them aren’t selling well.

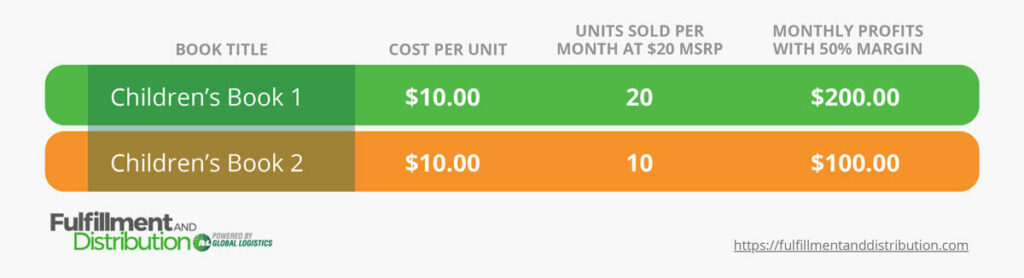

By kitting those two books together and discounting the final product, they increase their chances of moving the products and turning a profit. You can see how this plays out in the tables below.

This gives us a total of $300.00 profit between both titles. Let’s see if we can do better.

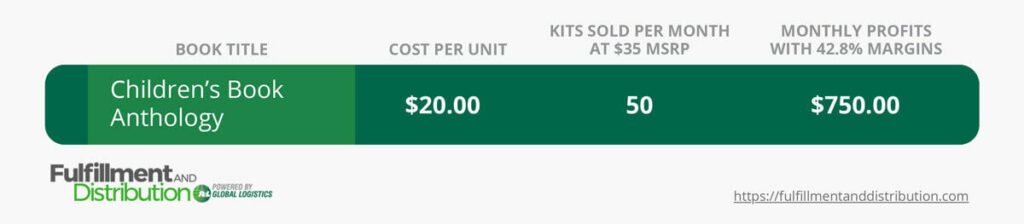

Since the titles aren’t selling as well as others, the shipper decides to sell them in a kit at a discounted price with a lower profit margin, which achieves the following results.

As an anthology, the books are boxed under one SKU at the shipper’s 3PL and sold as a kit. Buyers are incentivized by getting a deal on previously higher-priced merchandise, and shippers can move their slower-selling inventory.

With those advantages in mind, mistakes can occur during the kitting process. Businesses who aren’t familiar with the logistics aspect of this process can easily find their hard work ruined by customer complaints and shipping difficulties.

Related: Pick and Pack Warehouse: What You Need to Know

Several issues can arise from inaccurate packaging, and kitting does open up more opportunities for mistakes, simply due to the multiple components involved compared to a single item.

These errors can include:

For instance, an inexperienced warehouse worker might use packing tape to secure a box of hardware to an otherwise complete kit and neglect to print a separate shipping label for the hardware.

This can easily lead to the hardware box coming loose in transit. , with no separate tracking number, there would be no way to trace it. Everyone from the shipper to the customer ends up losing money and/or time.

This is just another reason to leave kitting in the capable hands of a 3PL with an expert staff who understands the ins and outs of storage, packing, and shipping.

Are you interested in introducing kitting as part of your business model? If so, don’t hesitate to contact Fulfillment and Distribution. We have over 20 years of experience in third-party logistics and have provided kitting services to businesses in a variety of different industries.

We also offer a full spectrum of logistics services for businesses of all sizes, such as

We understand that there’s no one-size-fits-all kitting process for businesses, which is why our team will work with you to find a solution that meets your specific needs and goals.

When you’re ready to get started, give us a call at (866) 989-3082 or request a quote online. We’re standing by to help you implement kitting strategies for your business.