Copy URL to Clipboard

Copy URL to Clipboard

Logistics yards are important staging areas for the throughput of freight shipments. Like any other aspect of logistics, managing these yards requires experience, an eye toward efficiency, and support from modern technology. Yard management is one of our top priorities at Fulfillment and Distribution. We’ll lend our experience to help you understand its importance.

Key Takeaways

Put on your outdoor clothes. It’s time to go play in the yard.

A warehouse yard, sometimes called a logistics yard, is the exterior portion of a warehouse where trucks are staged and some goods are stored temporarily pending transloading. In this context, yard management encompasses all roles, processes, and strategies that go into coordinating shipments from multiple carriers, storing goods temporarily, container positioning, and site security.

Let’s look at some specific positions in yard management and the duties they fulfill.

The warehouse yard manager is ultimately responsible for the yard’s performance. This position requires careful planning and scheduling to keep operations running smoothly. They often communicate directly with carriers to determine arrival and departure timeframes for freight shipments. Individuals in this position are also responsible for meeting safety compliance regulations and monitoring performance metrics like yard dwell time.

Yard managers must also oversee other roles in warehouse yard operations, such as:

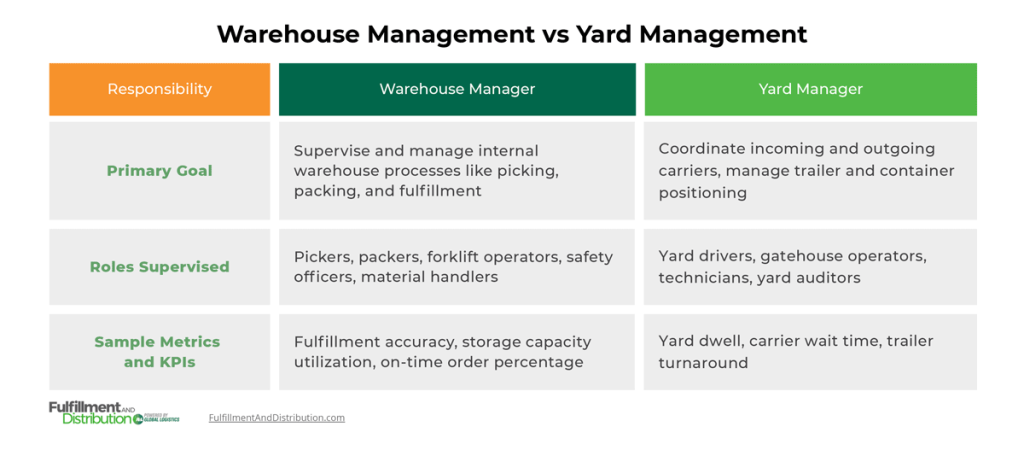

Warehouse management and yard management require similar skillsets, but there are some obvious differences, along with some more subtle ones.

Related: Fulfillment Optimization: Improving Distribution Potential

Both of these disciplines require focused, highly organized individuals working together to maintain the throughput of freight shipments. In the following table, you can see some of the notable ways warehouse management differs from yard management.

In order to meet the expectations of their clients and properly evaluate yard performance, yard managers rely on specialized software called yard management systems (YMS) to maximize performance and ensure accuracy of information.

A well-designed YMS helps managers keep track of the myriad data points they need to evaluate throughout the day. Specifically, it offers the following benefits for yard managers and workers.

If you’re new to logistics, setting up a yard management strategy and choosing the right YMS can be a daunting task. You can save yourself significant time by partnering with a third-party logistics provider (3PL) that already has these systems in place.

Related: How Warehouse Management Systems Work: Receipt to Fulfillment

Fulfillment and Distribution’s nationwide carrier network and 3PL warehouses are the resources your enterprise needs to thrive in a competitive environment. Call us at (866) 989-3082 or fill out a contact form online to discover all the ways we can help your business grow.