Copy URL to Clipboard

Copy URL to Clipboard

When your 3PL starts to hold you back, the best course of action is to find a company that can offer the logistics services you require. However, many businesses don’t know when or how to switch 3PLs. Understanding these two concepts is essential to make a smooth transition.

Key Takeaways:

By the time you’re done with this article, you’ll know how to fluently transition to a new 3PL.

Preserving the efficiency of your logistics operations is essential for every successful business. That means you’ll need to be able to identify when your 3PL starts to fall short. There are five tell-tale signs in particular that you should remember.

This includes:

I’ll take you through each shortcoming and explain why they justify switching to a new 3PL.

A good indicator you should switch 3PLs is when their service quality begins to diminish. This problem can take on a variety of forms.

It’s one thing if these problems rarely occur. However, if your 3PL consistently makes these mistakes, then it’s time to start looking for a new one.

The goal of every business is to grow. That’s why it’s important to have a 3PL that can adjust your logistics operations as needed. A 3PL provider that can’t help you scale up (or down) will only stifle the growth of your company.

Indicators that your current 3PL can’t help you scale your business include:

In some cases, 3PLs might struggle to scale down. This can be especially problematic if you’re adjusting to lower seasonal demand.

Practically every 3PL uses some type of software that helps them receive, store, and distribute bulk shipments on behalf of their customers. However, it’s essential they use the most current technology available.

If your 3PL is using outdated systems to perform their services, it can adversely affect your order fulfillment. Switching to a 3PL that uses up-to-date systems, allowing them to perform their services quickly and accurately, works in your favor. This will ensure your customers receive their bulk shipments in a timely-manner.

Increasing costs while service quality stays the same is another sign that you need to change your 3PL. Higher expenses should come with better services.

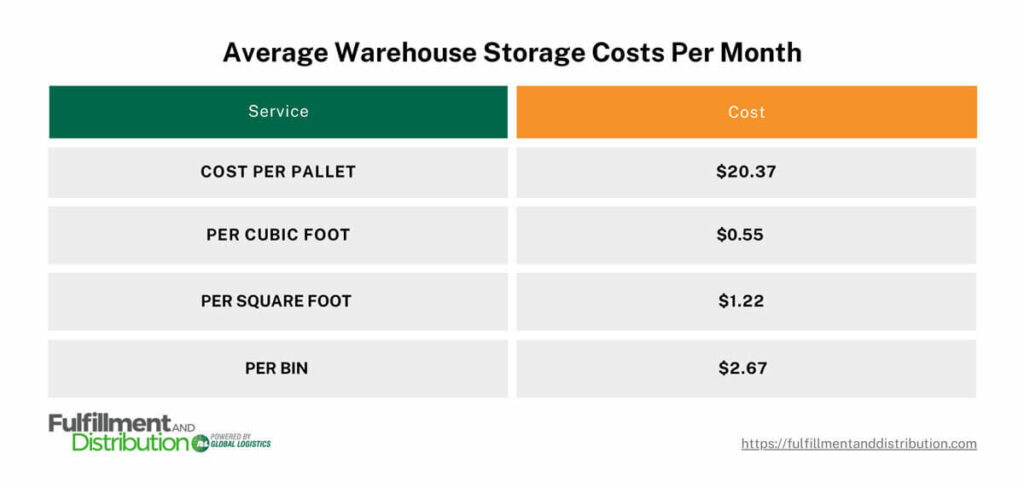

If your 3PL wants you to pay them more for the same services, then you’ll be wasting money that could be spent on a better alternative. Here are some average warehouse storage costs to give you a rough estimate on what you should be paying.

It’s important to note that costs might rise naturally over time. That said, excessively large hikes are still good justification that you need a new provider. There are plenty of 3PLs that will charge you fairly for quality services.

An effective line of communication with your 3PL is essential to successful logistics operations. Your provider should be giving you regular updates about your inventory, including:

If your 3PL isn’t communicating this essential information on a clear and routine basis, it can lead to a variety of problems that hinder the effectiveness of your supply chain. This will inevitably lead to dissatisfied customers.

Once you’ve decided it’s time to switch 3PLs, you’ll need to follow a few steps to make the transition. I’ve outlined each step you’ll need to complete in the following sections.

The first thing you should do is assess the logistical needs of your business. This will help you figure out what to look for when you start searching for a new 3PL.

Logistical considerations you should make before searching for a new 3PL include:

Certain 3PLs specialize in specific services, while others offer a wide range of solutions. You simply need to find the one that meets your unique requirements.

Related: Fulfillment Optimization

Now that you understand your logistical requirements, you can begin searching for a new 3PL provider. There are a few steps that you can follow to ensure you find the right one.

Following these steps will give you an inside look into the culture of a 3PL and the services they perform. You can then compare each of them and pick the one that’s the best fit for your business.

Once you’ve chosen a 3PL and formed an agreement with them, you should form your transition plan. The purpose of the transition plan is to help you move your inventory from your old 3PL to your new one seamlessly.

Here are the essential steps you should implement:

While following these processes will ensure you have a smooth transition plan, you may need to add more steps depending on your unique circumstances.

Related: How Warehouses Are Organized

You’ll need to notify your customers that you’ll be switching 3PLs. Even if you’ve developed a good transition plan, there’s still a good chance that orders might be delayed.

Letting your customers know that complications could occur will prevent them from being disappointed or upset when their orders arrive late. That said, be sure to tell them that you’re making the switch to a new 3PL to improve their experience as customers.

You can even outline the key benefits they’ll enjoy once your new 3PL begins handling your order fulfillment.

If you’re exhausted with your current 3PL provider, then Fulfillment and Distribution is ready to be your alternative. We have numerous logistics experts that can offer consulting sessions that will help you move your good from old 3PL to one of our facilities.

Our leadership has over 80 years of combined experience in the logistics industry. We also ensure our warehouses are manned by skilled and well-trained staff that will handle your goods with care. Fulfillment and Distribution’s warehouses are scattered throughout the U.S., which means you’ll be able to reach more customers than ever before.

Warehouse locations include:

Make the switch to Fulfillment and Distribution today by filling out your quote. You can also contact our team at (866) 989-3082 if you have any questions about the services we offer.