Copy URL to Clipboard

Copy URL to Clipboard

If you’re running a business that sells food products, outsourcing your warehousing operations can be extremely stressful. You’ll need to find a 3PL with a good reputation that abides by all federal guidelines. If anything goes wrong in the storage process, you’ll be looking at fines, sick customers, and damage to your brand. We’ll show you what to look for in a 3PL food-grade warehouse and how they can help your business.

Key takeaways:

Allow us to elaborate further on these points in the following sections.

Table of Contents

Storing food and distributing it across the U.S. can be challenging for your business. Fortunately, food-grade warehouses can provide valuable assistance in a variety of ways.

Regulatory compliance is a huge concern for businesses that sell consumables. Numerous federal agencies regulate these items to ensure they’re safe for consumption.

These include:

3PL food-warehouses follow the regulations of these agencies very closely. This will take the hassle out of having to complete all the applicable regulations yourself.

Maintaining product quality is another concern for businesses that sell food, especially for items that expire. Warehouses that specialize in storing food have the equipment needed to maintain the freshness and edibility of these products.

Storage and fulfillment operations for food require workers with specialized logistics expertise. You might not have that experience, which can leave a gaping hole in your business to be filled. 3PL food-grade warehouses are manned by logistics specialists. They can make up for the lack of transportation knowledge in your business by offering their skills.

Supply chain disruptions can stall new shipments from your suppliers. Keeping a fresh flow of food products stored in warehouses all over the U.S. ensures that your customers can still be reached. You can also scale your 3PL warehousing operations based on seasonal demand fluctuations.

Entrusting another company to handle the storing and fulfillment of your food products can be a huge step. However, food-grade warehouses implement different types of equipment and technology that guarantees the safekeeping of your items.

This includes:

3PLs also perform routine maintenance of the equipment in their food-graded warehouse. This prevents failures from occurring and guarantees the freshness and edibility of consumable items.

Finding a 3PL you can trust to store and distribute your food products is extremely important. We’ve identified key indicators that you should look for in a provider that we’ll discuss in more depth.

Your 3PL food-grade warehouse must comply with all applicable regulations. This includes adhering to guidelines set by the federal agencies we’ve previously mentioned. However, you should also check if the 3PL has certain certifications.

This includes:

3PL food-grade warehouses with these certifications allow you to verify their compliance with regulations pertaining to the storage of food.

When you vet a warehouse for your food products, you should find out what type of temperature and climate control systems it uses. Based on this information, you can determine the age of the equipment and how often they perform maintenance on it.

A warehouse that uses newer systems and performs routine maintenance is bound to be more reliable than older facilities with dated systems.

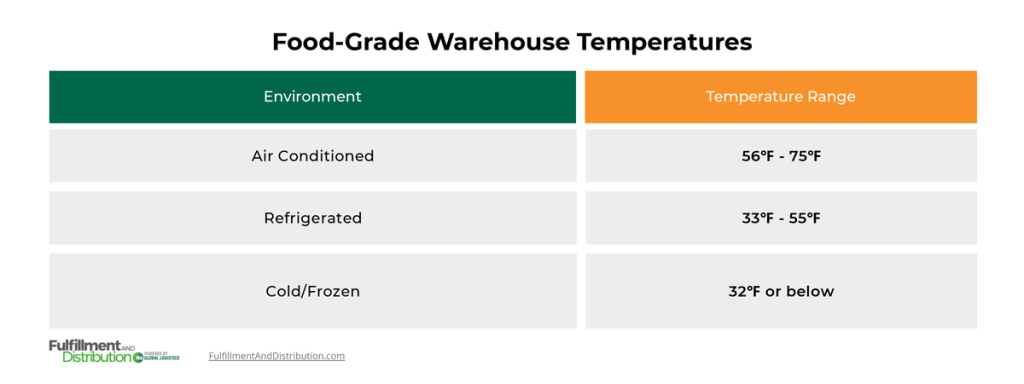

You should also find out what temperatures a 3PL’s warehouse can provide. Foods survive in different environments, which means it’s essential they store your goods in the correct conditions. We’ve provided a graphic that shows the temperatures your chosen facility should be able to achieve.

Finally, warehouses must implement temperature mapping and monitoring. Mapping uses sensors to measure temperature in different areas of a facility. Monitoring is the daily observation and management of temperatures inside different parts of a warehouse. These techniques work in tandem to provide the correct conditions for foods to survive in storage.

Any 3PL that stores your food should have real-time inventory management software that allows you to monitor your goods while inside their facility. This tool can help you check how much inventory you have in storage. You can use this information to make informed decisions of your stock levels.

Inventory management software also helps you identify your older food products and ensures they get shipped out first. Doing this is especially important for perishable items.

Should a recall occur, inventory management software can be used to trace affected food and quickly remove it from the warehouse. Identifying only contaminated batches will help you avoid throwing out products that are unaffected.

Related: Inventory Tracking Technology

Handling and storing food requires a high level of cleanliness and hygiene. This applies to both the warehouse and the workers inside. To verify the cleanliness of a warehouse, you’ll likely need to schedule a tour of a facility.

When you do, look for the following:

Cleanliness in a warehouse prevents contamination and guarantees the safety of your food products. This allows you to provide quality food that won’t run the risk of spreading illness.

When looking for a 3PL warehouse for your food items, make sure you find out where their facilities are located. Ideally, they should be close to grocery stores and supermarkets where your goods will be shipped. This will guarantee shorter transit times for your food, which is important if your goods are perishable.

Related: Reducing Logistics Costs

Many warehouses are designed to accommodate specific types of food.

Here are some common facilities you can use:

If you require storage for a variety of different products, then you’ll either need multiple warehouses, or a facility that can meet different temperature requirements.

Here at Fulfillment and Distribution, we have numerous warehouses all over the country where you can store your goods. Our facilities are manned by well-trained and experienced staff that will manage your inventory with care. We also provide an assortment of services, from pick & pack fulfillment to reverse logistics.

You can find our warehouses in cities like:

If you’re ready to get the warehouse services you deserve, then give our team a call at (866) 994-2602 or reach out to us on our contact page.