Copy URL to Clipboard

Copy URL to Clipboard

Retailers never want to end up with too much or too little of product. Ensuring they have the right amount can be a little tricky. However, demand planning can give you insights as to how much product you should have in the future. Before we get started, here’s some essential information you should know.

Key takeaways:

We’ll give you the full breakdown on demand planning and a detailed look on how you can implement it into your supply chain.

Demand planning is a supply chain management process that allows companies to predict future demand for their products and services. It allows businesses to make accurate projections that ensure they don’t end up with inventory overstock or stockouts.

Without a reliable plan in place, you’ll be forced to use unreliable metrics to make educated guesses about your future demand.

There are a variety of factors that can influence a demand plan:

Most companies try to predict demand anywhere between a few months to one year in advance. Ultimately, how far out you wish to project future demand will vary based on the unique needs of your business and the available data.

Creating and implementing a demand plan can be a challenge for many businesses. That’s why we’ve created a series of steps that you can follow when creating one.

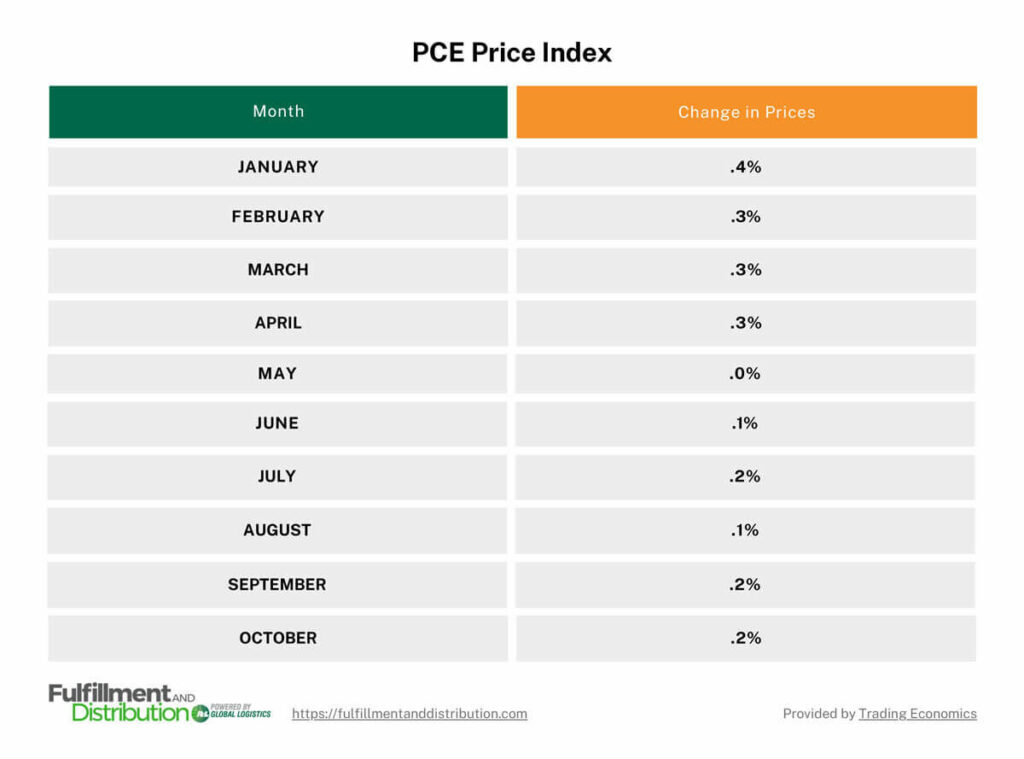

The first thing you’ll need to do is find the right type of inventory management software. Its purpose is to track your inventory levels, sales, shipments, and returns in real-time. You can also use the Personal Consumption Expenditure (PCE) Price Index to measure the change in prices that influence consumer spending. For example, consider the data provided between January and October 2024.

When price changes are higher, consumers may focus more on essentials or at least budget a little tighter. This data can be used to study past consumer behavior to predict what may happen in similar situations.

Next, you’ll need to gather and organize the data your inventory management software has collected. This will help you identify patterns in your demand and figure out what drives it and different points in the year.

To fine-tune your data, collaborate with members of your sales and marketing teams. They can provide insights that aren’t apparent in the data provided by inventory management software, such as:

Now that you have data that’s organized, you’ll need to use a forecasting method that you can put your data into. You can either choose a quantitative or qualitative forecasting method based on your needs.

After your forecast is complete, you’ll have a demand plan that will show you how much product you’ll need for the following week, month, quarter, or year. Simply order the appropriate amount of items you’ll need according to your plan.

Make sure you monitor your demand plan as you use it in your supply chain. There might be changes that occur which will necessitate some slight adjustments. You should also archive your old demand plans. They may reveal insights that you can use when you create a new one.

If a demand plan seems like it’s more trouble than it’s worth, then you should consider some ways it will optimize your business. We’ll go through the benefits that you’ll be able to enjoy in the following sections.

A good demand plan will help you optimize your resource management by telling how much product you’re going to need. This ensures you won’t end up with overstock that can take up space in your warehouses and increase your costs.

Likewise, a reliable demand plan will ensure you don’t end up with stockouts that lead to lost sales and dissatisfied customers. Your plan will also help you determine how to allocate other resources like manpower and capital.

This ensures you’re not over or underspending and that you’re utilizing the correct amount of labor needed to store and ship orders to your customers.

Demand plans, specifically ones that offer short-term predictions, take into consideration potential risks to the supply chain that could create increases in demand. Therefore, you’ll know about spikes in demand prior to them occurring.

You can act upon this information by taking the necessary precautions to prepare yourself. This might include building up your safety stock in anticipation for the rise in demand that will occur.

Since demand plans help you respond to future demand, your supply chain will become more responsive to industry changes. The added flexibility will give you a competitive edge over your competitors.

Demand plans don’t have to be set in stone, either. As we’ve already discussed, you can implement minor changes into your plan as you’re using it. This ensures you don’t become stifled when following your processes.

Fulfillment and Distribution has the resources you need to bolster your supply chain. Our leadership has 80 years of experience in the logistics industry. With their guidance, we’re able to provide a variety of warehousing solutions for your business.

You can even schedule a consulting session with one of our specialists. We have warehouses located in major cities across the United States. Each one is manned by well-trained warehouse staff that will handle your freight with the care it deserves.

Our warehouse locations include:

Get started with our services today by filling out one of our quotes. If you have questions about our company or services, then give our team a call at (866) 989-3082.