Copy URL to Clipboard

Copy URL to Clipboard

A stockout is challenging for any business, whether brick-and-mortar retail or ecommerce. Avoiding them completely is impossible, but reducing them and mitigating their negative effects should be a chief concern to any business owner seeking to build a loyal, satisfied base of customers.

Key Takeaways

Our guide will detail what causes stockouts, how to reduce their occurrences, and ways to lessen their impact on your business when they can’t be avoided.

A stockout occurs when a business’s inventory of a select item runs out of stock. When this happens, fewer products are available for customers, and profits drop. In 2022 alone, retailers in Canada and the United States experienced nearly $350 billion in losses stemming from stockouts.

Preventing stockouts is important not only to a business’s bottom line, but also in ensuring consumer loyalty. In order to understand stockout prevention strategies, let’s first examine what causes stockouts in the first place.

There are various reasons why a stockout might happen. No matter how it occurs, it can prove to be devastating in the short and long term.

Six of the most common reasons stockouts occur are:

Let’s examine how each of these reasons can manifest in a business environment.

Modern businesses live and die by the accuracy of their data. The following are various ways an incorrect data set can cause a stockout:

Anticipating delays and raw material shortages are essential aspects of inventory management. While some shrinkage is unavoidable, properly documenting and editing inventory to reflect that shrinkage will prevent you from overpromising and underdelivering.

The supply chain represents the entire fulfillment and distribution process from start to finish. Stockouts can happen at any point during this process. If a delay occurs during procurement, operations management, or retail fulfillment, it would be a direct result of supply chain stockout.

There are various stages of a supply chain, and stockouts can cause delays at any point during this process.

Whenever an issue in the supply chain happens, delays are likely to follow. Ultimately, delays translate into little-to-no available inventory. Thankfully, there are proven methods that can properly address a delay based on the specific situation. Through regional distribution and consistent sourcing, you will see better results in avoiding delays.

Manufacturers require raw materials to mass-produce goods for retail. Unexpected production delays can happen due to resources running out, issues during transportation, and other reasons that are hard to calculate.

Some common results from a lack of raw materials are:

By properly instituting data-based predictions, anticipating peaks in consumer activity and the life cycles of products your raw materials are needed for, you can increase your chances of having sufficient stock on hand.

We touched on the subject of shrink earlier, but it warrants further discussion. Not having enough inventory on-hand to fulfill an order, will lead to a few problems.

Types of shrinkage that can cause a stockout are:

For example, let’s say a customer is looking for a particular polo shirt on a website. When the customer sees that the retailer has one left in stock in their size, they complete the transaction online with a reasonable expectation that the item they wanted is available. If this shirt isn’t in stock due to shrinkage, your now-frustrated customer is likely to shop elsewhere.

Modern warehouses almost always use a software-based inventory management system. However, technical issues in the computer system can lead to stockouts.

Some areas where technical errors can create an out-of-stock scenario include:

The use of computer systems has some risks, but the upsides far outweigh the downsides. Highly skilled software engineers and technicians mitigate the likelihood of issues occurring.

In addition to technical issues, good old-fashioned human error can present itself in several ways. These mistakes can have a devastating effect on inventory accuracy and availability, and include the following:

In this case, manual inventory management opens the door to numerous possibilities for mistakes. Using warehouse automation such as a warehouse management system (WMS) will mitigate human error significantly.

Stockouts in ecommerce generally occur when the demand exceeds the projection of the forecasted trend. Thus, there is not enough available stock to fulfill all online orders in this situation.

This may occur under the following circumstances:

To avoid these issues, on-demand warehousing (ODW) through third-party logistics (3PL) is an effective solution.

When a stockout occurs, it creates a trickle-down effect for all involved. I’ve listed some of these effects in the table below.

One key area where a stockout can affect both the business and the consumer before a sale has even taken place is at the point of production. If required materials become unavailable, the manufacturer has to take action immediately.

Manufacturer issues that can lead to insufficient stock on hand include::

To fully understand how stockouts can damage your business, we can resort to some relatively simple mathematics.

In order to analyze your inventory to minimize costs and keep just enough stock on hand to meet consumer demand, you’ll need to calculate the cost of a stockout. Fortunately, there is a simple formula you can use to make this calculation.

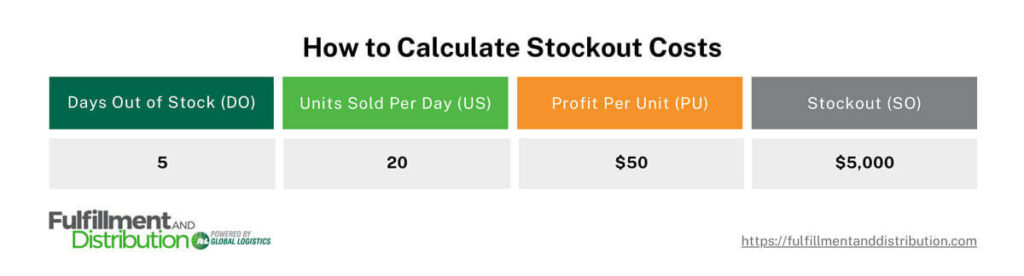

We multiply the days out of stock, units sold per day, and per-unit price. After multiplying all three figures, we get our cost.

In this example, let’s say your business sells electronics, and the demand for a new miniature tablet proves higher than expected. Let's figure out the stockout cost.

Using the formula (DO x US x PU) = SO, we can accurately calculate the lost profits from insufficient stock

Depending on the size of your business, these costs can prove to be catastrophic. Businesses that rely on high-volume/low-margin sales in particular can experience severe setbacks due to stockouts. This brings us to the question of how a business can avoid this situation in the first place.

Now that we’ve identified how badly a stockout can hurt your business, it stands to reason you’d want to prevent them entirely. Unfortunately, they can’t be prevented 100% of the time. We saw this during the COVID-19 pandemic, when even the biggest retailers in the U.S. couldn’t keep toilet paper or disinfectants on their shelves.

However, some stockouts can be prevented, and the following five techniques will help you do just that.

Whether you’re a manufacturer, ecommerce business, or brick and mortal retailer, preventative measures via inventory management are the best ways to reduce stockouts.

These measures encompass the use of advanced technology such as inventory management software in addition to many tried-and-true best practices. They include:

Another common technique used by businesses to combat the risk of stockouts is the purchase of safety stock.

Safety stock is extra inventory businesses keep on-hand to meet unexpected surges in demand. On the surface, employing this practice might seem a no-brainer. Why not keep as much stock on hand as possible? However, there are benefits and risks involved with safety stocks.

Benefits of this strategy include:

Meanwhile, keep these possible drawbacks in mind when deciding on safety stock levels:

The more accurate your sales projections, the easier it is to use this technique effectively to minimize out-of-stock scenarios.

Related: Safety Stock in Supply Chain: Surviving a Stockout

This technique is less about reducing stockouts and more about reducing their negative impact on your customer base. Whether you’re a B2B supplier or you work directly with end users, informed customers are happy customers.

If you know a stockout is likely to occur, passing that knowledge on to your customers can be beneficial for reasons such as:

Nobody likes to be surprised by finding out an item isn’t in stock. Going above and beyond with emails, flyers, signage, and outbound calls will set your business apart from those who don’t make this extra effort.

You might have a main supplier you routinely purchase goods from to maintain stock levels, but it’s never a bad idea to have other options. Here’s a common scenario I often encountered during my time in aftermarket sales.

There are disadvantages to this option, chiefly that you’ll take a hit on your profit margins by purchasing from a dropshipper instead of directly from a manufacturer. However, you might find it less costly than maintaining safety stock, especially if you don’t run into stockout issues very often.

Related: The Dropshipping Process: A Difficult Task Made Simple

By now, you’ve probably noticed that stockout prevention is a skill set unto itself. This is why growing businesses will often turn over inventory storage, management, and maintenance to a third party logistics (3PL) provider.

3PLs specialize in providing retailers, manufacturers, and ecommerce businesses with modern warehousing solutions that reduce stockouts and help you create a satisfied customer base. These providers can scale their services as your business expands, freeing you up to focus on your core competencies.

A stockout can occur from more than just one of the reasons covered. Sometimes, a combination of factors will cause them to occur. Partnering with a trusted third-party logistics (3PL) service is one of the most effective ways to avoid this issue. That’s where we come in.

Fulfillment and Distribution is the gold standard in distribution and fulfillment services. We’re here to serve you and ensure that your business has the best options in both distribution services and warehousing.

Our distribution and fulfillment services include:

Feel free to reach out to one of our friendly experts at (866) 989-3082 or fill out a contact form online today. We’re ready to partner with you to reduce stockouts and keep your profits high.