Copy URL to Clipboard

Copy URL to Clipboard

For some businesses, one supplier isn’t enough to meet consumer demand. Additionally, it’s often risky to rely on a single source for your products. That’s why many companies decide to implement dual sourcing into their supply chain. If you want to use this method, there is important information that you’ll need to know.

Key takeaways:

We’re going to dive deep into dual sourcing to show you how it can help your supply chain.

Dual sourcing is a method of using two suppliers to obtain any raw materials, products, services, or components. This supply chain strategy is utilized by a variety of business and industries.

Companies like these often face high demand and rapid technological changes. Dual sourcing helps them respond to these factors so they can keep their customers happy.

While dual sourcing is beneficial, not every business needs to implement this strategy. We’ve compiled a list of scenarios where using two suppliers can improve the functionality of your supply chain.

Developing a dependency on one supplier can become a serious problem. For instance, if your one supplier raises their prices, you’ll have no choice but to suffer a financial hit.

Instead, you could find a second supplier that offers cheaper prices for the items you sell. You can buy most of your product from your second supplier, while keeping your first one as a backup for emergencies.

Dual sourcing will also boost your supply chain. Using one efficient supplier is great, but having a second will give your business an edge over the competition.

There are numerous circumstances that can negatively impact the supply chain, resulting in stockouts. Fortunately, multi-sourcing is a great way to circumvent a variety of challenges.

These include risks from:

When one supplier is hindered by supply chain disruptions, you can lean on your second supplier to compensate. They’ll be able to keep you afloat while your other supplier deals with the issues facing their operations. By dual-sourcing, you’ll be able to keep risk low and stay flexible when the supply chain takes a hit.

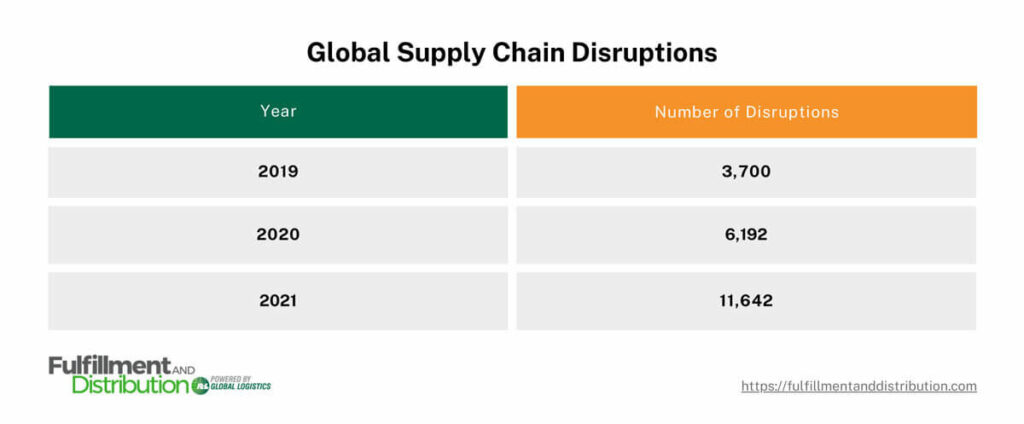

To demonstrate how vulnerable the supply chain is to risk, consider some data I’ve provided on supply chain disruptions between 2019 and 2021.

There were numerous causes for these disruptions, with the COVID-19 pandemic being the most prevalent. The start of the Russia-Ukraine in 2022 exacerbated issues facing the supply chain as well. There are other interferences that are less reported, such as factory fires, mergers and acquisitions, and labor disruptions.

You’ll need to provide more products to a larger customer base to scale your business. Maybe your current supplier can’t provide you with the items you need. Instead of finding a replacement, you can simply find another supplier to supplement your first one.

Dual sourcing also allows you to shorten your lead times, which is very important when you’re scaling your operations. You can stagger your shipments from each of your suppliers. This will help you keep a constant flow of product to your growing customer-base.

Dual sourcing can help you support customers in different regions of the country. This helps expand the reach of your business.

You can use suppliers in different regions of the country and set up warehouses near each one. As a result, you can fulfill orders for customers in different regions.

This will help lower the shipping costs that are tied to long haul and cross-country deliveries.

Related: Safety Stock In Supply Chain

Demand fluctuates for most industries at different points of the year. When demand slowly rises, a second supplier can help you by increasing your capacity to keep up with orders. While order volume can increase gradually, it’s possible that emergency situations will cause a dramatic spike.

Dual sourcing allows you to respond faster than you would be able when using only one supplier. This ensures you won’t miss out on any opportunities to make more sales when demand rises.

Related: What Is Demand Planning?

Dual sourcing can be useful in a variety of circumstances. That said, implementing two suppliers into your supply chain should be done carefully. Fortunately, you can follow a variety of steps to ensure your dual-sourcing strategy is successful.

The first thing you should do is identify the vulnerabilities in your supply chain. Taking some time to evaluate your needs will help you determine what type of risks you want to defend against. Afterward, you can start looking for suppliers that will help you prevent these risks.

Make sure the suppliers you’re searching for are located in different regions. Sources that are close to one another will likely face the same supply chain challenges if they occur. Choosing two providers in different locations reduces the chances that both are disrupted at the same time.

Vetting your suppliers is another important step. You’ll want to make sure each one will be able to perform reliably. Fortunately, there are a variety of characteristics that you can identify to guarantee you make the right choice.

After you’ve selected the two suppliers you want to use, you’ll need to make sure to balance out orders between each one. This will ensure you receive a steady flow of goods. Make sure you carefully monitor the performance of your suppliers to ensure they’re providing the best service.

Factors you should look out for include:

Finally, you want to keep a clear line of communication with your supplier. This will ensure you can update them about orders and provide them with valuable information they can use to perform their services.

Dual-sourcing is a great strategy to implement into your supply chain. However, there will be some challenges you’ll need to address.

This includes:

When you have two suppliers, you’ll have to negotiate a business arrangement between each one. This should be done carefully to ensure you come to an agreement that benefits you, and your provider.

No two suppliers are exactly the same. They all employ slightly different methods to perform their operations. Although this isn’t bad in of itself, you might need to make slight adjustments to your business processes to accommodate for these differences.

That said, you shouldn’t have to completely change how you run your operations. This is why it’s important to carefully vet each supplier carefully to ensure they’re the right fit for you.

Quality control (QC) practices between your suppliers are one of the bigger challenges. The best course of action you can take is to find two suppliers that use QC processes that are similar to each other. This will ensure there is uniformity in the quality of products you’re able to sell.

Fulfillment and Distribution has the resources you need to manage your inventory. We have warehouses all over the country that will help you reach new customers in different regions. Our facilities are manned by well-trained warehouse staff that will handle your goods carefully.

You can find our warehouses in the following locations:

You can set up a consulting session with one of our warehousing professionals at (866) 989-3082 to discuss the services we can provide. If you already know what services you require, then fill out your Fulfillment and Distribution quote.