Copy URL to Clipboard

Copy URL to Clipboard

When selecting a warehousing and third-party logistics (3PL) provider, consider factors such as:

All of these factors play a key role in your ability to enhance your operational efficiency and should impact your decision when choosing a warehouse provider.

Like any other business partnership, choosing a third-party logistics (3PL) provider requires careful consideration of several factors. Making the right choice can boost profits, while getting it wrong can lead to customer dissatisfaction and severe damage to your bottom line.

Key Takeaways:

Join us as we lay out the most important considerations business owners should take into account while choosing a third-party logistics partner.

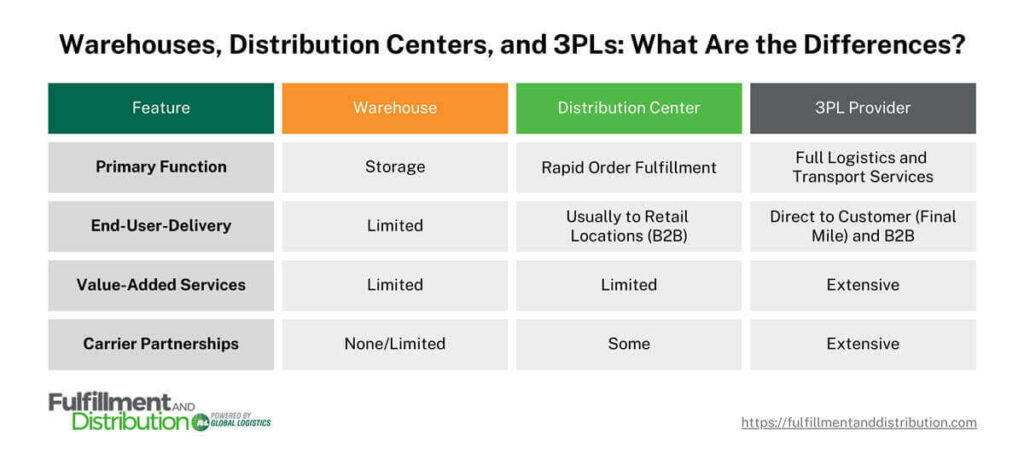

At first glance, warehouses, distribution centers, and 3PLs may seem interchangeable. However, understanding their differences is crucial to building a logistics strategy with business goals.

In the chart below, I’ve compiled some features of these different facilities for easy comparison.

Since 3PLs incorporate warehouses, distributors, and carriers into a network of facilities and fleets, they can scale services appropriately for businesses large and small. However, not every 3PL is created equally. Before picking a provider, you’ll want to evaluate a few factors to ensure you’re getting the best possible service at a price that lets your business keep growing.

When choosing a 3PL, the sheer number of factors for business owners to consider can be overwhelming. However, the most critical elements generally fall into five categories:

Let's examine each of these considerations in detail.

Related: 3PL Warehouse Locations

The geographical location of your 3PL directly impacts shipping speed, freight costs, and customer satisfaction. A strategically located provider ensures fast delivery to your target markets, reducing lead times and improving the overall customer experience.

Breaking down the importance of location comes down to two key elements:

Of course, a smart warehouse location strategy is only useful if the 3PL has the carrier relations necessary to move goods out quickly and efficiently.

The strength of a 3PL’s carrier partnerships determines their ability to adapt to market fluctuations and ensure competitive shipping rates. A diverse carrier network enables greater flexibility, especially during peak times such as holidays and tax return season.

Full-service 3PLs should also have access to carriers with specialized equipment like reefer trucks for perishable goods that require specific temperature and humidity conditions while in transit.

By working with a diverse carrier network, a 3PL can more easily implement distribution strategies that save money and time for its clients.

As a business grows, its need for multiple storage and distribution options increases. A robust 3PL should offer a wide range of warehousing and distribution strategies tailored to different inventory types and fulfillment models.

Some common warehousing fulfillment strategies are:

Distribution strategies are equally important to meeting consumer expectations while reducing unnecessary fuel costs. These include the following:

A flexible provider capable of implementing multiple warehousing and distribution strategies will help your business remain agile even when difficult situations arise.

Related: What is a Bonded Warehouse?

Modern 3PLs rely on advanced technology to improve the accuracy and visibility of their operations for their clients and partners. Automating processes via specific types of software and/or hardware plays a critical role in reducing labor costs and preventing errors. A few examples of these technologies are:

By working with the most up-to-date technology, 3PLs drive efficiency across the supply chain, ensuring fast order processing and reduced fulfillment errors.

Related: Types of Warehouse Management Systems

A top-tier 3PL offers more than just warehousing and shipping—they provide value-added services for their clients. As a business owner, these services can free you up to focus on marketing, customer research, and other ways to grow your enterprise.

These are just a few of the services a third-party logistics provider can add on top of their traditional offerings:

These services improve the customer experience from purchase to delivery, differentiating premium 3PL providers from basic warehouses.

Choosing the right warehouse provider is a cornerstone of supply chain success. By focusing on the elements we discussed above, you can be certain your 3PL provider will position business for scalable growth and enhanced customer satisfaction.

Fulfillment and Distribution is a strategic partner offering comprehensive 3PL services to businesses of all sizes. These services include:

Call us today at (866) 989-3082 or get a risk-free quote online. We’re standing by to help fulfill all of your business’s logistics needs.