Copy URL to Clipboard

Copy URL to Clipboard

Inbound and outbound logistics are both critical to the successful management of a fulfillment warehouse. When properly optimized, they help a business keep the right balance between inventory management and distribution services.

Key Takeaways:

Explore the different aspects of inbound and outbound logistics to find the right solutions for your business supply chain as a whole.

Inbound and outbound logistics are the driving forces that push products through the supply chain from inception to consumption. Both rely heavily on effective shipping, but for different reasons.

Let’s quickly outline each process.

The items themselves can range from being raw materials used in manufacturing to the finished product waiting on final delivery.

The focus with most outbound logistics will be to ensure the client receives the products as ordered and within the specified time frame.

If you are a warehouse manager or business owner, think of it this way. When you are managing inbound logistics, you are often the client. When you manage outbound logistics, you are a seller. What happens to products in the interim depends on where in the supply chain your business operates.

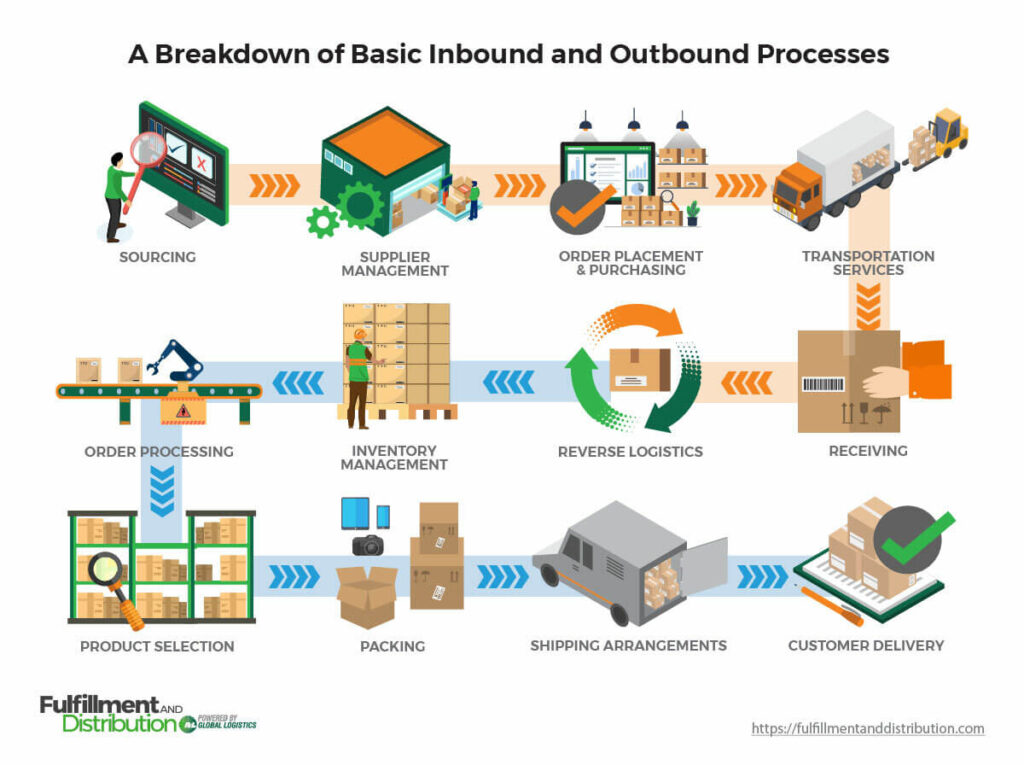

Before we go into an in-depth review of specific services, it's good to see them laid out as basic steps.

These represent the two ends of a business supply chain. Inventory management can fall into either inbound or outbound services, depending on how an individual warehouse is organized.

In either case, it’s a process that both sides need to ensure is operating successfully. Let’s take that in-depth dive into each side now.

You can also refer to inbound logistics as the receiving processes. These are materials that are entering a warehouse or retail center.

As mentioned, the received items can be raw materials, components, or even final products. The steps taken as part of the inbound process are going to differ depending on the business’ involvement with the products.

Inbound logistics processes begin well before you receive anything in your warehouse. Starting with finding materials and mostly ending with reverse logistics management. I’ll go through a basic review of each one.

Warehouses that are selling fulfillment services or operating as manufacturing centers must have materials. Items need to match the standards and needs of the facility.

Building supplier relationships will help when it comes to price negotiations, setting up delivery schedules, and ensuring accountability for product quality.

Timing and order quantity factor into logistics because you’ll need to make sure you have room to receive the items and a plan for items with limited shelf life. Orders that must be shipped internationally need to account for customs duties. Too much or too little in an order can have equally negative impacts down the line.

Modern supply chain management struggles with transportation mean you need to stay on top of which carriers you’re hiring (or were hired by the seller), fuel prices, and lead times. Truck, rail, or air — these all get lumped in with inbound logistics management.

Make sure you have space to receive new items, technology to track incoming orders, and a reliable putaway process.

Although technically its own area, the logistics behind returns still requires tracking the item, confirming its condition, restocking, and making it available for purchase again if possible.

Receiving (and reverse logistics) flows straight into inventory management, and then eventually will connect with outbound processes. An updated warehouse management system, well-trained staff, and organized storage areas will all make this easier.

Related: Procurement vs Logistics: The Money and the Movement

To make sure that your inbound processes are working well, you need to track specific key performance indicators (KPIs). Not only will they help you uphold a standard of performance, but they’ll also help with pinpointing problem areas.

Useful KPIs to use as metrics for inbound logistics include:

These are all metrics that focus on ensuring your operations, cost, and product quality are tracked. Managers can use KPIs to see where improvements need to be made either in terms of organization, technology, or employee training.

At times, it may serve as an indicator that it’s time to switch suppliers or update equipment. While it’s good to set performance goals, both for growth and maintenance, realize that there’s no perfect system. Even a great setup is going to need to deal with challenges.

Some struggles in logistics are beyond anyone’s control. As the saying goes, you can plan for everything but the unexpected. Of course, you can always try, which is why we’re reviewing three of the most common challenges for inbound freight management.

These expenses are unavoidable, which is why they present a challenge. Shipping prices can vary widely and are impacted by seasonality, economics, and even politics. For the inbound process, you’re the client and thus your options for shipping costs are likely smaller. This is especially challenging if you have routine orders set up, but not a locked in rate, which places you more at the mercy of fluctuating prices.

Whether it’s an order that came in early, or an influx of products that have suddenly risen in demand, surges tend to slow down inbound processes. It can be a struggle to find where to put incoming shipments, ensure there are enough people working, and make sure everything is still entered into the WMS correctly.

Higher than expected shipping costs as well as surges often result from a lack of general information from your supplier. Final costs of shipping, estimated delivery times, and shipment tracking are all critical pieces of information for the management of inbound logistics. When access to these is delayed or just difficult to access, unhappy surprises increase.

Related: Inbound Logistics Optimization

Outbound logistics processes begin once customers have placed their orders. Once again, these processes may be carried out differently depending on your customer base. Fulfilling orders for individuals and bulk orders for businesses means managing different volume levels, which may alter some of your practices.

In either case, many aspects of outbound logistics can also be handled with an efficient Order Management System (OMS).

Once again, let’s break down the specific activities and processes of outbound logistics.

There are a significant number of details attached to client orders:

Whichever of these options you currently offer or plan to, the goal is to get them all right, every time as much as possible. An order management system (OMS) that fully integrates with your WMS is a good start.

This is any means by which the items ordered by the client are gathered together. The more complex the order, the longer it will take, and the more mistakes are possible. There are multiple order picking strategies to choose from to ensure the methods match the business model.

Once products have been picked, they need to be packed. The exact type of packing depends on the method of fulfillment. Whether it’s small items getting placed in a box or large boxes placed on a pallet, the goal is the same. Get the shipment to the buyer in the expected condition.

Outbound shipping arrangements should strike a balance between customer preference and affordability. Managing the logistics aspect means knowing the capabilities of your preferred carrier services, route costs, and even insurance rates to better know what you can offer clients.

To meet the demands of the modern consumer, your outbound logistics should feature technology such as track and trace. Other logistical considerations would be the availability of lift gates, expedited services, and white glove depending on the type of product being handled.

Outbound processes are client facing and thus capable of impacting others’ perception of your company. Most businesses rely on repeat customers, or at least on the good reviews that happy customers may leave behind.

When it comes to tracking KPIs, the metrics that help manage spending and efficiency will be just as important as the ones that inform you about customer satisfaction.

Tracking the appropriate KPIs through your WMS and related systems will help you catch potential bottlenecks and other error-prone procedures. Just as with inbound processes, some challenges will be harder to overcome than others.

Fulfillment services, which is essentially what outbound logistics are, involve many moving pieces. Technology, people, and processes all have to work within a limited space and time frame. Seamless interaction between these three entities is an uphill battle.

Technology frequently updates, employee turnover within the warehouse industry remains high, and processes are always being tweaked slightly based on the latest KPIs in an effort to boost performance. Add to this the fact that busy warehouses are filled with the physical comings and goings of people and equipment.

Coordinating all of it so that people aren’t running into each other or being left waiting for a previous task to be finished will always be a challenge.

As with inbound processes, the cost of doing business is an issue in and of itself. Running a warehouse is expensive. Investing in people and systems to streamline activities comes at significant cost. Meanwhile, the goal is still to run a business that makes a profit.

On their own, inventory storage costs can sneak up on a business because they impact other areas of your business. Too much inventory raises storage costs, but it also impacts the amount of other inventory you can get, including products that may sell better.

Clients expect more from companies than ever before. If you’re in the business of fulfilling to customers directly, then same-day deliveries, free deliveries, and other near instant gratification policies are often expected.

While B2B client expectations may not be as high, especially in terms of expecting free deliveries, the standards are still high. Managing customer expectations, B2B or otherwise, becomes less about offering them everything they want and more about clearly communicating what is available.

Trying to meet every expectation is next to impossible, not to mention expensive. The challenge lies in finding the happy medium between the operational costs involved and keeping clients happy enough to wait for deliveries as needed and still come back as a repeat client.

Avoid thinking of inbound logistics versus outbound logistics as though they are in competition with each other. In the end, they are both vital to keeping your business running.

For ecommerce businesses, improving your warehouse performance is a huge part of that. You can’t necessarily wow clients with a storefront or in-person customer service. However, ensuring that they get what they order, in the right condition, right specification, right price, and have it arrive when they’ve been told it will—that’s gold.

It starts with having clear, attainable performance standards. Optimization typically comes into play under two circumstances:

In both cases, you start off by examining the data. Don’t have data? Well, you’ve just found the first thing you can optimize. I’m going to walk you through technology upgrades and a few other suggestions.

Which of these optimization ideas you implement will depend on what your own data systems tell you. Realize that even when you are meeting KPIs, there is always room for improvement.

Outside your actual warehouse operations, it’s also a good idea to also take the time to strengthen relationships with the suppliers and carriers you routinely work with. Good communication is a key part of supply chain visibility.

Setting up warehouse logistics, tracking the data, and then making sure to apply changes as needed is an exhausting, never-ending process. When your goal is to run a successful business, it’s often better to outsource responsibility to another company that is already set up for it.

Fulfillment and Distribution offers third party logistics services, including warehousing, that can handle inbound and outbound processes for your company. We’ll keep you in the loop so you have access to all the data necessary to help the other half of your business.

Warehouses can manage:

Call today at (866) 989-3082 to speak with an experienced and knowledgeable representative or get a direct services quote and begin improving your logistic services today.