Copy URL to Clipboard

Copy URL to Clipboard

There’s nothing quite as disappointing to a business owner as having a great week in sales only to see return requests start trickling in. Whether it’s due to damages in shipping, errors in fulfillment, or cores for remanufactured items, returns are a fact of life in commerce. However, working alongside an experienced 3PL can take the sting out of reverse logistics and processing returns.

Key Takeaways

Let’s back up and examine the key elements of the reverse logistics process.

Understanding the key terms in reverse logistics can help businesses streamline their processes and enhance customer satisfaction. Here are some essential definitions:

By 2028, the global value of reverse logistics is expected to grow to $909.87 billion, a percentage increase of nearly 25% from 2024. This serves to illustrate why shippers need an effective returns process in place that balances customer satisfaction with preserving profitability.

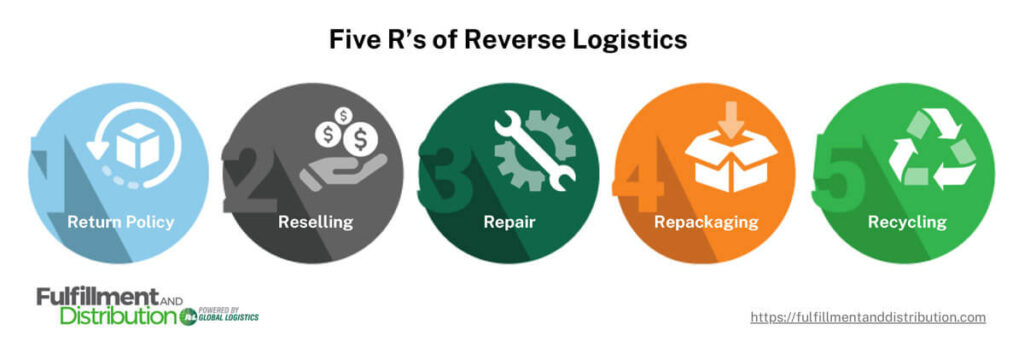

The reverse logistics process can be broken down into the following five basic steps.

On a general level, these steps cover everything from the customer’s return request to how returned goods are reconciled by shippers and warehouses. Let’s examine each of these five steps in the process more closely.

A business’s return policy must clearly explain:

A 3PL that can handle reverse logistics on your behalf will most likely use warehouse management software (WMS) to automate the pure shipping and storage elements of this step.

Additionally, a modern WMS should integrate with your chosen ecommerce platform, so your 3PL will be able to tell if a return is authorized or not.

Related: Putaway Process: A Thorough Guide to Efficient Warehousing

For retailers, repair is often the best-case scenario in a return transaction. If a customer receives a broken product and agrees to repair per your particular RMA process, it’s true you’ll lose some money from shipping charges and time during the repair itself. However, you’re likely to retain more profit (at least in the short term) than you would from other return options.

Common circumstances under which a customer might opt for repairs include:

Most return policies require the customer to send goods back for inspection, even if they’re not willing to wait for repair. Even if you have to send an immediate replacement, you may be able to salvage the value of returned goods via remanufacturing or refurbishment.

Products that undergo one of these two processes are sometimes known as remans or refurbs. Whichever process is used, the purpose is essentially the same: to transform an unsaleable item into one which can be sold.

However, there are important distinctions between remanufacturing and refurbishment.

Both of these processes involve repairs. However, in reverse logistics, the ‘repair’ option is used when the end user is willing to send defective merchandise back, wait for it to be fixed, and then sent back to them. This maintains a closed loop between buyer and seller. Remanufactured and refurbished goods are almost always sold to new end users.

Retailers may return large amounts of goods that don’t sell well. For shippers, kitting in warehousing is an option you can use to create value for your customers and move poorly-selling merchandise.

When a product is returned, it may require new packaging to make it ready for restocking or resale. Repackaging ensures that products retain a new, sellable appearance and are protected from further damage, allowing businesses to recapture value from returned items rather than taking a loss.

Here are several ways a 3PL excels at repackaging in reverse logistics:

Effective repackaging by a 3PL prepares returned products for resale and enhances brand recognition. With experienced third party logistics providers, businesses can focus on growth while their returns process is expertly handled.

Though it can be considered a worst-case scenario, recycling components from merchandise that is otherwise unsaleable is sometimes the best option. This is especially true of modular goods such as home computers.

A fringe benefit that comes from a solid recycling plan is sustainability. Environmental concerns have become a key component of customer decision-making over the last several years. Partnering with a 3PL whose expertise and partnerships accommodate this need will have a positive impact on the perception of your business.

There is an appeal to handling every aspect of your business first-hand, but turning logistics over to professionals can prove beneficial in several ways, such as:

If all of that sounds like a lot of work, guess what? It is. Wouldn’t you rather devote your time and resources to building your brand and meeting the needs of your customers? If so, the good news is that by outsourcing reverse logistics to a 3PL, you can do just that.

From single-item ecommerce transactions to large-scale returns and denial of shipments, shippers can’t afford to lag behind the competition when it comes to reverse logistics. You need a clearly defined returns process with multiple options to mitigate customer dissatisfaction and the resulting dent in profitability.

That’s where we can help.

Fulfillment and Distribution’s 3PL services include modern reverse logistics solutions powered by up-to-date WMS and years of experience. By partnering with us, you can ensure that your returns are being handled professionally while you concentrate on issues like gaining market share and increasing profitability.

We can also assist your business with:

Don’t let returns throw your business goals into reverse. Call us today at (866) 989-3082 or submit a contact form online today.