Copy URL to Clipboard

Copy URL to Clipboard

When your business runs out of inventory, it can lead to lost sales, customer dissatisfaction, and a negative perception of your brand. Utilizing safety stock is a great way to prevent taking that kind of business hit. Here are some important things you should know before you start building up your backup inventory.

We’ll show you how safety stock can benefit your business and carefully explain the formulas you can use to calculate your product reserves.

Safety stock is extra inventory that businesses keep on hand to prevent shortages or stockouts. It can also be referred to as buffer stock or backup inventory.

Events that may necessitate the use of safety stock include:

By having reserve inventory ready, businesses can fortify themselves against risk and ensure they always have available stock ready for their customers.

Related: What Are Stockouts?

Having reserve inventory is great, but you need to make sure that you don’t have too much or too little available. Fortunately, there are multiple formulas that you can use to calculate how many items you’ll need.

This includes:

In the following sections, I’ll explain each formula and show you how to use them when calculating your safety stock.

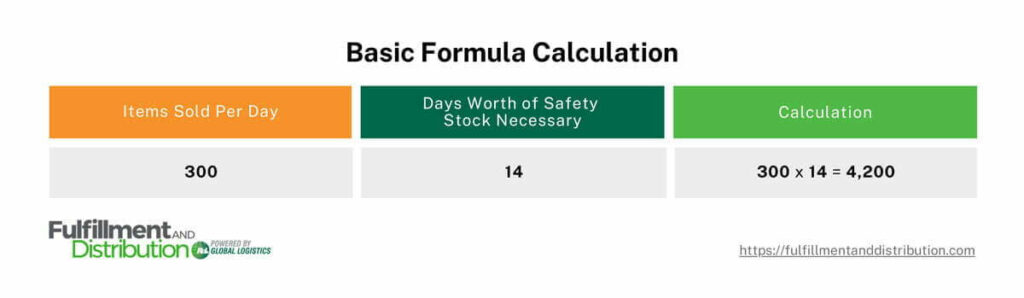

The Basic Formula is the simplest method of calculating backup inventory. Essentially, this formula works by multiplying the number of products sold each day and multiplying it by the number of days worth of safety stock you require.

I’ve provided a graphic using hypothetical numbers that will help you visualize this calculation.

Based on this calculation, if you sell 300 units of a certain item each day, you’ll need 4,200 items for 14 days worth of safety stock. While the Basic Formula offers a simple way to calculate backup inventory, it doesn’t take into consideration other factors like demand and lead time variations.

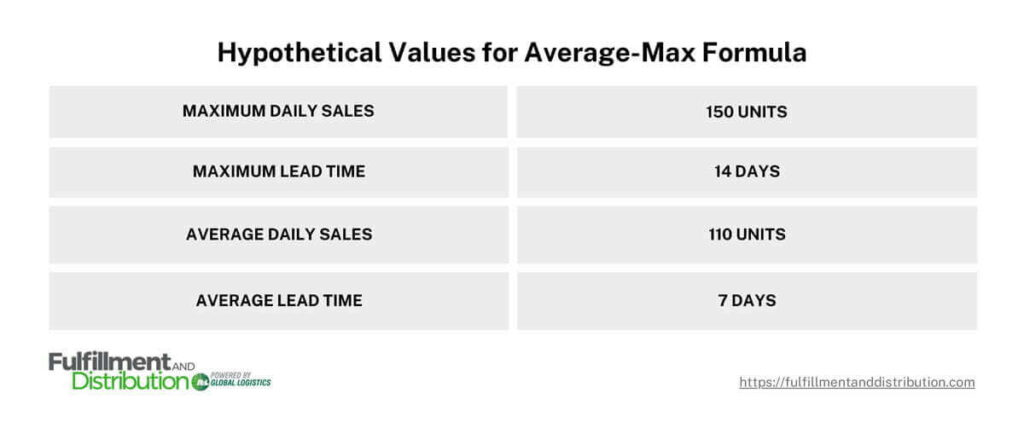

The Average-Max Formula allows you to estimate your backup inventory by looking at past variations of lead times and sales. Using these past metrics, you can make an assumption of what will happen in the future when you protect against the highest of supply and demand variations.

Before showing you the formula, it’s important to know what each value will represent.

Now that you know the values, here is what the Average-Max Formula looks like:

Safety Stock = (Max Lead Time × Max Sales) — (Average Lead Time × Average Sales)

I’ve provided a graphic that shows data we’ll use for our hypothetical calculation.

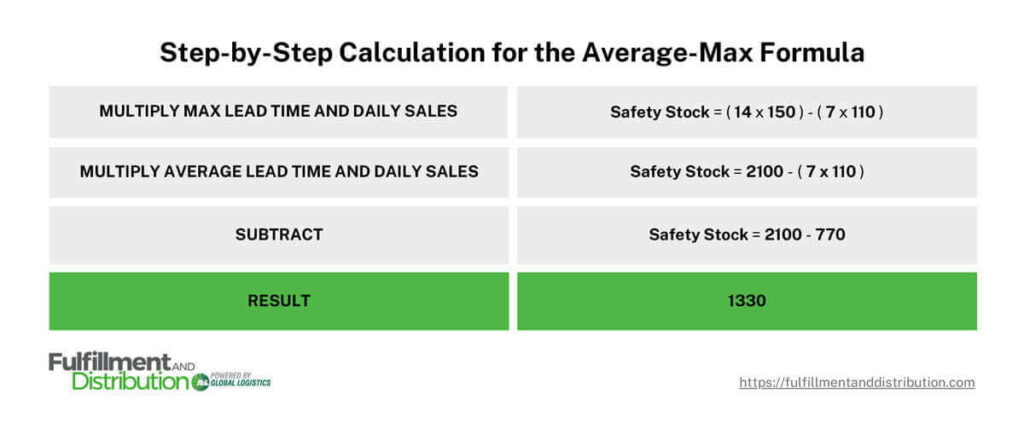

Using the numbers we assigned for each value, we can move on with our calculations. I’ve provided another graphic that will show you how to perform the Average-Max Formula.

Based on these calculations, your business should keep 1330 units of safety stock to manage fluctuations in demand and lead time variability.

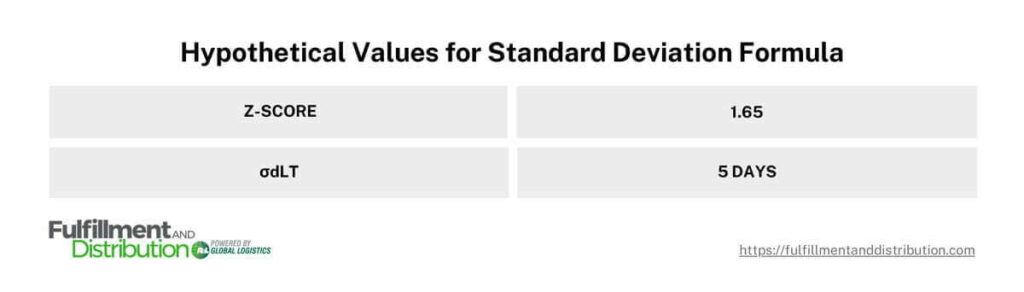

The Standard Deviation Formula, also known as the Heizer & Render’s formula, is used to measure the amount of variation in your lead times.

It is represented as:

Z × σdLT

To help you understand this formula better, I’ve provided a list that shows you what each value represents.

Let’s move on to our calculations. Consider some hypothetical data that will be ascribed to the Z-Score and standard deviation of lead time.

A Z-Score of 1.65 represents a service level of 95%. For the sake of simplicity, we’ll continue to use 1.65 as the Z-Score for all subsequent examples.

Using the values we’ve provided, all you need to is multiply:

1.65 × 5 = 8.25 units

Since the product is a decimal, you can round down to eight units. It might seem that eight units of safety stock is inadequate. The next formula we’ll discuss will build upon this one and allow you to calculate backup inventory more efficiently.

Greasley’s Formula allows you to calculate fluctuations in both lead time and demand. It looks exactly the same has Heizer & Render’s Formula, except you’ll be factoring in average demand. This is represented using the abbreviation Davg.

Here is the formula:

σdLT × Davg × Z

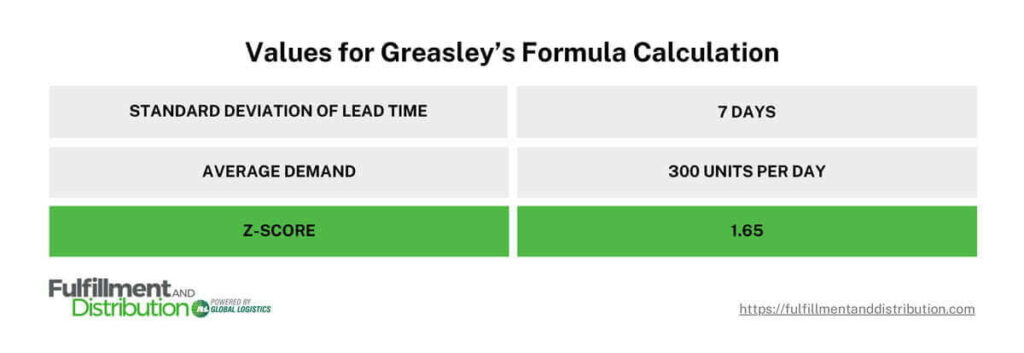

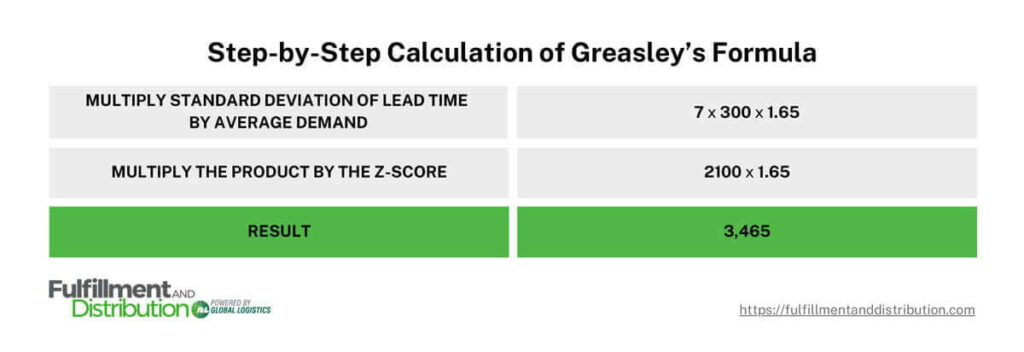

Now that you know the formula, let's start with some hypothetical data that we’ll use for our step-by-step calculation.

I’ve provided the calculation for these values in the following graphic.

To maintain your service level, you’ll need 3,465 units worth of safety stock for seven days. While the Heizer and Render Formula has its benefits, the Greasley method is a more accurate way of calculating buffer stock because it allows you to consider multiple variables.

The primary purpose of backup inventory is to prevent stockouts or low product levels. That said, it can be managed and used for a variety of other purposes.

Fluctuations in demand are often predictable. However, events like shifts in customer trends, panic buying, and natural disasters can cause a dramatic spike in demand. Keeping buffer stock on hand will help you to better respond to these challenges.

Similarly, forecasting demand for new items can be difficult as well. It’s difficult to predict how a new product will sell when you won’t have any historical data to use. Demand forecasts can also be inaccurate due to their inability to analyze every risk that could negatively impact the supply chain.

Supply chain disruptions can prevent you from receiving timely resupply for your items. Keeping an adequate amount of inventory reserves will ensure you have enough items to sell until your product levels are replenished.

Finally, proper management of safety stock prevents the need for expedited shipments of new inventory. Instead, you can start using your reserve products until a normal shipment of new items arrive. This will help you save money on expedited shipping costs.

Calculating, managing, and using your buffer stock effectively is a lot of responsibility. Fulfillment and Distribution has the resources you need to ensure you always have the correct amount of reserve inventory ready for emergencies. You can even schedule a consulting session with one of our team members to determine how much you’ll need.

Once your safety stock is in one of our warehouses, you can trust our well-trained warehouse staff to handle your goods carefully. You can find our facilities located in major cities around the country.

Set up your backup inventory today by filling out your Fulfillment and Distribution quote. You can also contact our team at (866) 989-3082 to set up your consulting session or if you have any questions about our services.