Copy URL to Clipboard

Copy URL to Clipboard

Managing inventory and fulfilling orders can be difficult for growing businesses. Fortunately, 3PL warehouses and the operations they perform can help. Before using one, there are a few key points that you’ll need to understand.

Key takeaways:

I’ll teach you about 3PL warehouse services, how they work, and why they’re beneficial to the rest of your business operations.

A third-party logistics (3PL) warehouse is a facility that provides storage and distribution services to various companies. They help businesses streamline their retail processes by allowing them to focus on their core functions.

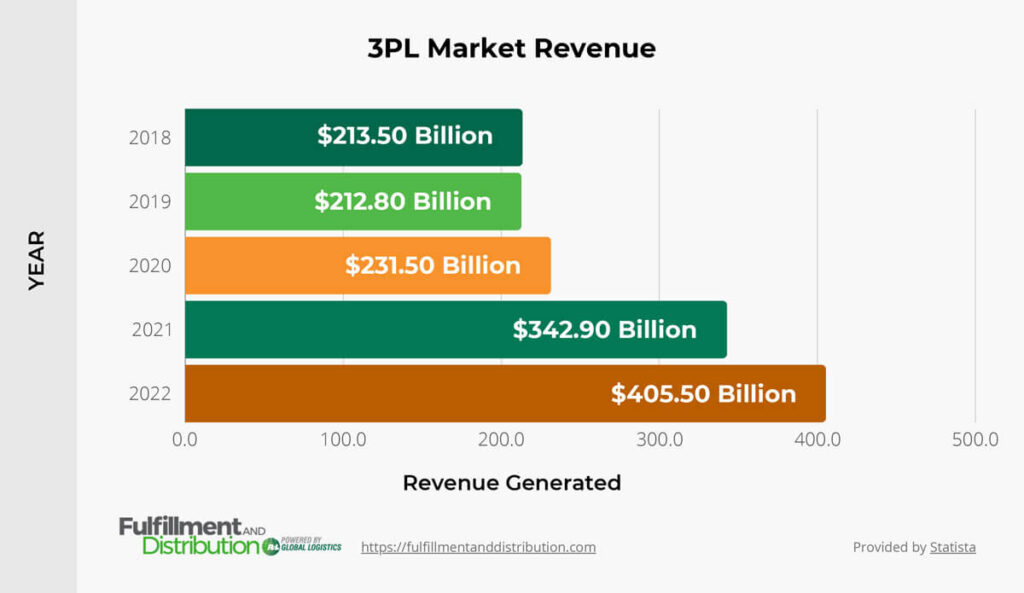

3PL warehouses have become a popular option for many businesses in the United States as a means of outsourcing these operations. To show their growth, I’ve provided some data on the revenue the market has made in recent years.

As the numbers show, 3PL warehouses will be used more and more as the years go on. If you’re ready to experience the difference one can make, Fulfillment & Distribution is ready to help.

3PL warehouses perform a variety of services:

In the following sections, I’ll explain each operation and how they work.

3PLs need to receive goods before they can send it out to a customer. When the items arrive at the warehouse, personnel will conduct a thorough check-in process.

During this time, they check for:

Goods will then undergo a quality control check. The products are entered into warehouse management software for visibility. Each SKU that’s stored is in a designated area of the facility.

Items can be kept in the following places:

It’s important for retailers to work with a 3PL partner that has enough storage space and the right environment for their goods.

A business that needs to bring in bulk amounts for peak seasons may want to ensure they can scale up or down easily. Features, such as temperature control, are needed to keep certain products safe.

Warehousing is a cornerstone service that goes beyond mere storage.

These services are great for businesses that need to outsource order fulfillment to a third party retail shipping warehouse to compensate for the space they lack.

The picking process starts soon after a customer submits an order. 3PLs will prioritize each load based on urgency, product, shipping method, and buyer requirements. This ensures that time-sensitive shipments will receive the attention they deserve.

3PLs retrieve purchased goods using three common strategies:

Each of these methods reduce errors during the picking process. Afterward, a 3PL will perform another quality check of the ordered items before they’re packed and palletized.

When the items in the order have been picked, it’s time to start packing. The packing phase may require meticulous attention to detail to safeguard items during transit and maintain the integrity of the order. This is especially true when multiple items are sent together.

Many packing materials will be used, such as:

When picking and packing are combined, they form pick and pack fulfillment services. 3PLs will also verify the weight and dimensions of the packages or palletized load. Information about the shipment is included in all applicable documents.

If products being ordered are large or come in a secure box already, additional packing may not be needed. This could be the case for certain types of flat-pack furniture or even large appliances.

Loose packages and palletized loads come with shipping labels attached. These also contain details about the cargo and ensure the shipment can be tracked throughout the supply chain.

After an order is packed, it’s time for shipping. The speed of transport depends on what is offered by a business. Most carriers can provide anything from standard less-than-truckload (LTL) to expedited delivery.

3PLs will pick a shipping provider from their network that’s best suited to handle the load. They also find carriers that offer the best quality at the best price.

After the item is shipped, warehouse management software can push tracking information into your ecommerce or business enterprise system using a shipping API. This means businesses and customers can easily track orders as they travel to the final destination.

Customer returns tend to be an inevitable part of business. Whether the client simply isn’t satisfied with a product or it arrives damaged, businesses will need reverse logistics services.

This operation consists of:

A 3PL partner can include shipping labels with each order to ensure returns make it back to the proper warehouse. This can be convenient for businesses, as they won’t have to handle returns in house. Additionally, customers can also track the status of their return as it moves through the reverse logistics process.

When you’re shipping goods to a customer, storage is often unnecessary. That’s why many 3PLs offer cross docking services. Cross docking is when a shipment is unloaded from an inbound vehicle to an outbound vehicle. The service minimizes storage time and ensures freight travels seamlessly to the final destination.

You may find it useful to use multiple modes of transportation to ship goods to your customers. To accommodate for this need, 3PL warehouses offer transloading. This service is performed by unloading freight from one mode of transport and loading it onto another.

For example, you might use a train to carry your goods for the majority of the journey, and then utilize a truck to perform the delivery. In this scenario, a 3PL would be able to transition your freight from train to truck.

Using the services of a 3PL warehouse isn’t a requirement when running a business, but it can be helpful in a variety of situations. I’ve listed a few scenarios where you may want to consider implementing these operations.

Many 3PLs have warehouses located throughout the country. If you’re trying to reach more customers, then using a 3PL can help expand your selling potential.

During certain parts of the year, you’ll likely notice an uptick in sales. For small and medium-sized businesses, it can be difficult to keep up with orders. The operations performed in a 3PL warehouse can help pick up the slack.

When you’re managing inventory and shipping out orders, you might find yourself distracted from the business tasks you’re better suited to perform. Hiring a 3PL warehouse to provide their services will give you more time to focus on the core responsibilities of your business.

Related: Five Types of Warehouse Storage Systems

Hiring a 3PL warehouse can make managing your inventory and fulfilling orders much easier. In the following sections, I’ll explain the benefits you can expect to enjoy when using one.

Keeping track of stock levels and shipping products can be difficult when order volume is high. Performing these tasks can be even more difficult if you don’t have enough staff to help you. Outsourcing these operations to a 3PL warehouse can remove these responsibilities from your to-do list.

They have the equipment and technology required to perform these tasks on your behalf. With the help of a 3PL warehouse, you won’t need to hire as much staff, invest money in warehouses, or inventory management systems. This will help you reduce your expenses.

If you have a small business, and you’re experiencing growing pains, then a 3PL warehouse can help you scale your company. As your company grows, your logistics needs will grow with it.

A 3PL can fill these gaps in your supply chain by providing their services. You can also scale down warehouse operations when order volume starts to slow, providing a dynamic logistics solution for your business.

Many 3PL warehouses use modern and state-of-the-art technology that assists them with their operations. Rather than investing in a system of your own, you can rely on a 3PL to perform efficient inventory management and order fulfillment.

Related: Five Benefits of Outsourcing Inventory Management

While you might have knowledge about running a business, logistics is an entirely different subject. 3PL warehouses have skilled logistics professionals that have years of experience in the industry.

The workers in these facilities are also carefully trained to handle your products. Outsourcing these operations is more affordable than putting these professionals on your payroll. It will also eliminate the need to learn these operations yourself.

Fulfillment & Distribution can be your premiere 3PL provider. We can provide you with a variety of warehousing services for your goods. Our workers are also trained to use state-of-the-art technology, while abiding by strict safety practices.

We guarantee your goods will always arrive in perfect condition. On top of our vast array of services and our skilled workers, we also have a nationwide network of warehouses.

This includes the following cities:

If you’re ready to feel the difference Fulfillment & Distribution can make, fill out your quote today. You can also contact our team at (866) 989-3082 if you have any questions about the services we provide.