Copy URL to Clipboard

Copy URL to Clipboard

How a warehouse arranges their order picking can have a significant impact on their fulfillment speed. Batch picking is just one strategy a business can explore, especially if it has high volumes of similar orders to fulfill.

Key Takeaways:

Learn how fulfillment batching is being used in warehouses to streamline pick & pack orders while improving customer satisfaction.

Fulfillment batching, also known as batch picking, is a strategy that organizes orders so that exact or similar orders are grouped together and gathered by a picker at the same time.

The goal with this order picking strategy is to optimize each picker's efficiency. Of course, it’s only truly effective with the right training and follow-up processes to also ensure accuracy.

In general, batch picking can be implemented in three different ways:

The size and complexity of your inventory and warehouse space will influence which strategy to consider. There are pros and cons to each

In the next section, I’ll walk you through the ideal batch picking process.

As with any successful picking strategy, fulfillment batching starts with efficient order processing. Warehouses should be investing in one or both of the following to get started.

Ideally, you would have an OMS that can fully integrate with your WMS. The WMS provides the needed inventory management tools integral to internal warehouse operations. The OMS secures your ability to offer customers flexible payment systems and omnichannel experiences.

The Fulfillment Batching Process

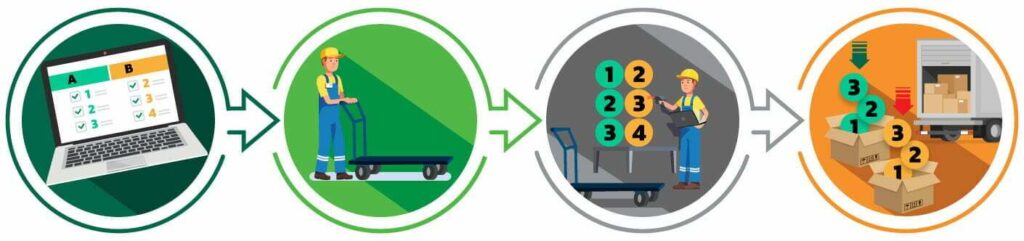

With your management system in place, batch picking can proceed as follows:

The more order history you build up, the better you’ll be able to organize SKUs and related services. Changes in customer buying habits or popular products should be tracked as well so that SKUs can be reorganized as needed.

As an example, we’ll consider a warehouse that fulfills orders for an eCommerce vendor selling medical scrubs in bulk.

Forty orders have come in and the WMS has sorted them into eight batches, each covering five orders. The orders in each batch all contain the same or similar items, which means the picker can gather all the items for five orders with minimal stops.

While there may be the occasional order that goes against the grain, data trends are usually a good indicator when studied over a length of time. Even in that case, you can still set up the WMS to produce batching lists that come with a recommended picking route.

This will ensure that all SKUs, even the random outliers, are still gathered in the most efficient way, minimizing picker travel time. Depending on the size of the warehouse and the complexity of the shipments, batch picking can be combined with other strategies.

For more information on other order picking methods, check out our article on seven warehouse order picking methods that can improve accuracy and efficiency.

No matter which batch picking strategy you go with, the goal remains the same: complete as many orders as possible, as quickly and as accurately as you can.

When implemented and maintained correctly, the practice of fulfillment batching does exactly that in the following ways:

These benefits are dependent on how well the fulfillment batching process is organized to begin with. A big part of that is employee onboarding and training. Current labor shortages in warehouses can place extra stress and duties on the employees that are present.

Providing a safe working environment for employees and giving them good training may help. Employees who feel secure with their skills for the job will be more confident, perform better, and be less prone to making mistakes.

For all its advantages, batching picking doesn’t work for every warehouse or business model. A significant amount of prep work needs to be put in place, and it’s more tailored to warehouses with high SKU overlap.

Before switching to a fulfillment batching strategy, warehouse managers should consider the following traits:

Some of these disadvantages can be managed with strategic warehousing and employee training. Others are there as a sign that you may be better off with an alternative strategy.

Warehouse managers need to take a close and honest examination of their operation to determine if picking multiple items at once is even possible with their current setup.

When you begin using fulfillment batching, certain trends are going to become more apparent. First are foremost, these should be used to streamline the system you initially started with.

The longer you use the system, the more data is collected that can be used to a company’s advantage. Long-term, your overall fulfillment efficiency and inventory management will improve.

As with the benefits, how much more efficient the warehouse becomes will be a combination of how well the strategy is implemented and whether it matches with the business model.

Fulfillment logistics are complicated. Even with all the new technology at your disposal, finding the right solution may take some trial and error.

You can save yourself some of that hassle by partnering with us at Fulfillment and Distribution. We have the space and manpower to handle different fulfillment strategies. If we can’t do it, our warehouse consultants can help you find someone who can.

Whether you need fulfillment batching, custom order picking, or kitting services, we’ll get you the right partner for the job. We also offer various freight consolidation services alongside our warehousing, including.

Get a service quote today that’s tailored to your unique needs. You can also give us a call directly at (866) 989-3082 to speak with a warehousing representative..