Copy URL to Clipboard

Copy URL to Clipboard

Figuring out how to improve outbound logistics is an important part of growing any business. It also happens to be one of the most rapidly changing parts of the shipping industry. As ecommerce sales continue to grow and traditional retail stores close down, customer expectations drive innovation in this significant aspect of the supply chain.

Key Takeaways

Learn the basics of outbound logistics, the modern issues complicating this process, and five ways you can improve it.

In simple terms, outbound logistics is the process of goods being sorted, packed, shipped, and delivered to the customer. The end user delivery aspect is known as final mile service. Outbound logistics can apply to consumers (the aforementioned end user), retail locations, and even other links in your own supply chain.

This contrasts with inbound logistics, which is focused on goods or raw materials your business receives. Depending on where your company operates on the global supply chain, your outbound logistics operations might be someone else’s inbound logistics processes. This is more true if you work with raw materials in creating finished products.

For example, if your company manufactures leather goods, your inbound services may include raw cowhides. Your outbound logistics management would be focused on getting your finished products to retail stores or a distribution center being used by an ecommerce retailer.

Prior to the advent and popularization of ecommerce, outbound logistic processes looked the same for many years. Business to business (B2B) shippers would pack their pallets, load their trucks, and deliver the shipment to its final destination (usually a retail location). There would have been very little contact between the carrier and the end user.

The rise of shopping online, coupled with expectations for faster delivery, forced carriers to adapt and certain challenges became apparent.

Among the most significant of these challenges are:

The rising importance of customer satisfaction has played a role in some of these challenges. With so many options now available to potential clients, many companies feel the need to increase the variety and volume of their goods.

Without proper management processes in place, however, inbound and outbound logistics can become overwhelmed with such variety. It's better to find ways to work smarter rather than harder.

Knowing what the challenges to the industry are, you can plan out strategies specific to your business needs.

Why is this so necessary? Consider the impact each separate challenge can have on the overall shipping process. For instance, take something as simple as diesel fuel prices. These prices fluctuate not just from day to day, but from one geographic location to another.

If a truck is delivering across multiple states, it makes sense to fuel up at the stations with the lowest fuel costs along the route. Now, scale that up to fleets of trucks making multiple deliveries in a day, and the importance (and difficulty) of reducing fuel costs increases dramatically.

This is just one aspect of outbound logistics that can be improved to minimize costs. So, what steps can you take to optimize this and other outbound logistics processes?

There are five major steps a business can take to improve this vital aspect of the logistics process.

Let’s take a closer look at how each step contributes to the optimization of outbound logistics.

By carefully evaluating different delivery strategies, businesses can reduce costs, streamline operations, and meet customer expectations more effectively.

Here are three common shipping strategies, along with scenarios where they provide value to shippers and carriers alike.

Point-to-Point Delivery: This relatively simple strategy involves transporting goods directly from the origin to the destination without intermediate stops.

Example Scenario: An ecommerce retailer shipping small, high-value packages directly to customers can benefit from point-to-point delivery. The method reduces transit time and avoids delays that could occur at sorting facilities.

Benefits:

Hub-and-Spoke: The hub-and-spoke model consolidates shipments at a central hub (warehouse or distribution center) before dispatching goods to final destinations.

Example Scenario: A retail chain delivering inventory to stores across a region could use a central distribution hub. Goods are first sent to the hub, sorted onto pallets, and then distributed to stores in smaller shipments.

Benefits:

Milk Run Delivery: Named after early 20th century dairy product delivery methods, a single vehicle makes multiple stops to pick up shipments, which are delivered to a single destination.

Example Scenario: Your business ships components to a manufacturer for final assembly. Instead of delivering them point-to-point, you consolidate your shipment with those of other component manufacturers who send goods to the same final assembly plant.

Benefits:

Re-evaluating your delivery strategy depends on your business size, delivery volume, and geographic reach. By selecting a strategy that aligns with your business needs, you can ensure that no resources (including money) are wasted during the delivery process.

Inventory storage and management is something of a middle point between inbound and outbound logistics. Accurate inventory is needed so you know when to order more and how much you still have available to sell.

As a business grows, so does inventory complexity. While there may have been a time when a handy spreadsheet and a weekly hand count were all you needed, things have changed.

With an order management system (OMS), you have the ability to automate these processes and get real time number updates. An OMS is often at the core of a strategic warehousing plan.

These are just some of the metrics and information an OMS can track:

Not only will an OMS allow you to get a transparent view of your operation, but it will also give you access to valuable data. The ability to generate reports to track ordered items, fulfillment speed, and more means you gain insight into trends in real time.

Transparent communication is at the core of an ideal customer experience. This doesn’t mean a bombardment of constant notifications, but rather focused messages relevant to customer orders.

Some of the previously mentioned OMS systems have mobile options that allow messages to be shared directly with customers via text or an app specific to your company. They’re often designed to integrate with warehouse management systems (WMS), providing a seamless exchange of data that helps you avoid stockouts that can lead to lost sales and dissatisfied buyers.

Useful information and services to provide for customers could include:

The easier it is for customers to find out what’s going on with their orders, the more satisfied they are. Even if you can’t always provide the fastest service, being up front about delivery times - even if it takes weeks - is better than promising a rapid service with which you can’t follow through.

Another significant digital upgrade for your business is to begin using an electronic data interchange (EDI) system. Where OMS and customer communication tools are meant to stay internal, an EDI streamlines communication between you and any outbound logistics business partners.

Depending on whether your focus is B2B or B2C, this could mean direct customers or the shipping service you use for final services. Either way, an EDI is intended to provide an electronic and structured system for the exchange of business documents.

Because it can integrate with your current OMS, it serves as an instant communication tool. Do you have customers asking delivery drivers for updates on other packages? By using an EDI, even contracted drivers working out of different systems can send those updates quickly.

There are multiple types of EDI services from which to choose, depending on your business needs.

Each type of EDI System has its pros and cons. Likewise, putting an EDI into practice requires your company to have an existing OMS or WMS system to store the data.

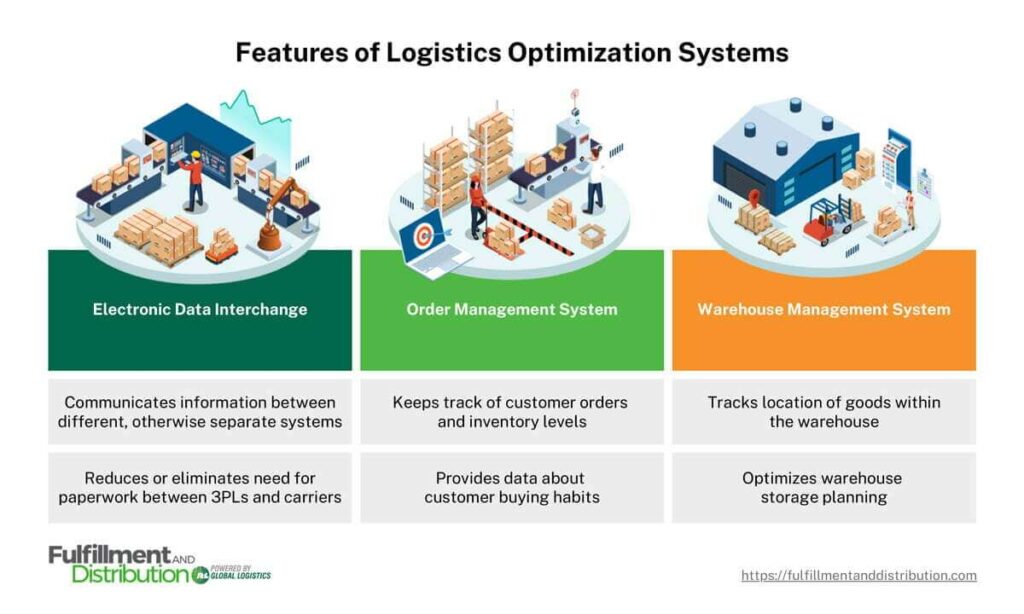

To clear up any potential confusion about the differences between an OMS, WMS, and EDI, I’ve compiled some features of each system in the graphic below.

Once you do have an EDI system in place, communication with business partners and clients should be clearer across the board. In some cases, you may even be able to provide timed deliveries within a 15-minute window.

Finally, you can choose to expand your business by partnering with a third party logistics company, or 3PL.

On a basic level, 3PLs can provide warehouse management services and help you find carriers to pick up and distribute your goods. Choosing a 3PL provider is a big step, especially when you might be used to controlling so many parts of your logistics operations directly.

With that said, growing businesses often find that outsourcing logistics to a 3PL pays for itself in time saved to pursue other goals, such as refining products and growing their customer bases.

Do your research and be sure to choose a provider with a proven track record of warehouse management, capable of vetting carriers to ensure your goods are safe in transit. If you need special services provided, such as pick and pack, make sure to inquire about these needs as well.

The number of systems I’ve mentioned throughout the article can easily seem overwhelming to implement. This is another advantage of partnering with a 3PL, since many of them will have these systems in place already.

A 3PL can provide those services because they often move multiple goods from different companies. Experience is on their side for many factors.

As online markets continue to grow with current consumer practices, working with a 3PL gives you the ability to grow local and possibly nationwide sales.

Want to learn more about how a 3PL handles different sides of the supply chain? Check out our article on procurement vs logistics.

As you can see, refining your outbound logistics strategy is a necessity as your business grows. Few businesses are able to scale up their logistics operations while simultaneously addressing marketing, customer retention, and other duties. That’s why so many of these businesses choose to partner with a 3PL like us.

Fulfillment and Distribution works with businesses of all sizes to provide warehousing and delivery services, including outbound logistics. With our network of warehouses, distribution centers, and carrier partners, we can handle all of your logistics needs while you focus on growing your company.

Our full list of services includes:

Give us a call at (866) 989-3082 or get a risk-free quote today. Our team of logistics experts is standing by to help you grow your business.today.