Copy URL to Clipboard

Copy URL to Clipboard

A penny saved is a penny earned, and logistics costs can add up to a pretty penny indeed. Between fuel, storing your merchandise, and handling, charges are abundant. Keeping those costs under control should be a high priority for businesses of any size.

Key Takeaways

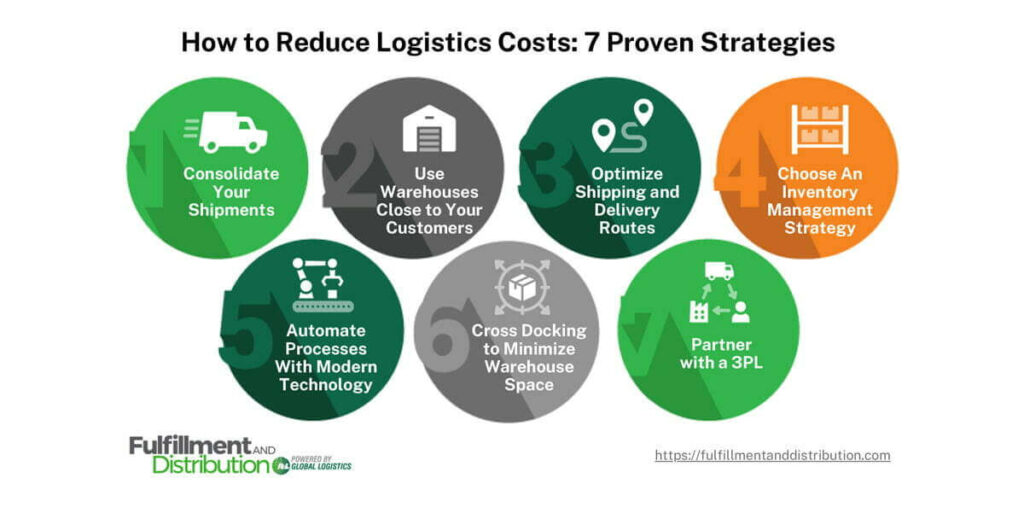

Join us as we review seven ways businesses can reduce their logistics costs.

To place these cost-saving tactics in their proper contexts, let’s start by categorizing the sources of these costs within the greater practice of logistics.

Now that we have identified these general costs, we can more effectively find ways to minimize them.

So, how can logistics costs be reduced? The shortest answer would be one word: optimization. Reducing costs in any business comes down to making the most out of available resources. In the case of logistics cost management, that usually means controlling fuel costs and the price of warehouse space.

The following seven steps apply optimization to key areas of logistics, helping reduce excess costs that result from wasted resources.

Let’s take a look at each step in greater detail to see how each one can save you money.

As a shipper, one of the most important decisions you’ll need to make is between full truckload (FTL) and less-than truckload (LTL) freight for your shipments. To briefly address the differences between the two methods:

Since LTL shipments are consolidated in this manner, shippers only pay for the space they need in the container, not its entirety as they would with FTL. This makes LTL shipping more affordable in than FTL in most scenarios.

Executing an LTL strategy to save money isn’t easy, and working with experts in the logistics industry can greatly simplify the process.

Whether you run a small ecommerce business, a retail location, or you strictly sell business-to-business, proximity is key to reducing shipping times. Less time in transit means less money spent on freight charges and happier customers.

If you’re in ecommerce, and you ship nationwide, analytics from your ecommerce platform and search engine dashboards can provide insights into areas where your end users are most heavily concentrated. For instance, it’s common for customers to be clustered in large population centers like southern California.

Having warehouses and distribution centers located nearby will save you money on fuel and make it easier to meet customer expectations regarding delivery times.

If you need to store imported goods for an extended period of time, find out how a bonded warehouse can save you money.

Your inventory management procedures are another logistics process to explore for cost-effective practices. There are three common inventory management strategies.

These logistics procedures determine how goods leave storage and go to customers. There are benefits to each of these, depending on your business model.

For instance, LIFO doesn’t make much sense to businesses initially. It seems counterproductive to some to hang onto old things. For an industry that deals in perishables, that would be absolutely right.

However, let’s say that you are running a lumberyard. The price of lumber has climbed and each new load you receive is valued higher than the last. Selling off the higher-value wood first may save money when calculating your inventory taxes later.

Not every state charges an inventory tax, but for those that do, LIFO is a worthwhile option. It works for someone running a lumberyard, or similar non-perishable commodities because wood isn’t likely to go bad when stored properly.

In terms of logistics expenses, cost control has more to do with spending wisely than just aiming to spend less.

Related: What is an Inventory Tax?

A study conducted by Argonne National Laboratory estimated that semi trucks consume up to one billion gallons of fuel per year just while idling. While some idling can’t be avoided, poor route optimization can lead to excessive fuel waste.

By using route optimization software, logistics providers can significantly reduce unnecessary fuel expenditures. Modern trucks combine optimization software with fuel economy optimization systems, which can reduce fuel usage by up to 31%. All of these savings amount to more money staying in your pocket at the pump.

Route optimization software isn’t the only advanced technology that can save you money in the logistics process. Warehouses with automation systems in place boast high levels of efficiency, which lead to cost savings in the long run.

Some examples of this technology include:

These systems contribute to a speedy, efficient flow of tasks within a warehouse and help reduce fulfillment costs.

In cross docking, inbound shipments are directly transferred from the receiving dock to the outbound shipping dock, with minimal or no storage in downtime. This distinguishes cross docking facilities from warehouses in two important ways.

Implementing cross docking can significantly reduce logistics costs in the following ways:

By employing cross docking, businesses can significantly cut logistics expenses while maintaining efficient product flow and a high level of service.

Taken individually, each of the previous steps can play a part in reducing your logistics costs. However, our sixth tip combines the previous five tips into one simple way to bring your shipping and warehousing costs down.

Third-party logistics (3PL) providers are experts in executing every step in the logistics process at a high level. These include:

Think about all the work that goes into making your business successful: marketing, manufacturing, and understanding what your customers are looking for are all jobs in and of themselves.

So is managing logistics, and partnering with a 3PL will ultimately save you money and give you more time to fulfill other roles.

From storage to shipment, micromanaging the logistics process is one of the best ways to reduce its associated charges. However, doing so is a time-consuming affair best left to professionals with access to varied tools and networks that reduce complexity as well as overall costs.

That’s where we come in.

At Fulfillment and Distribution, we have decades of experience partnering with businesses to handle all aspects of the logistics process. We can easily scale up 3PL operations to meet your needs as you grow your customer base.

Our shipping and warehousing services include:

Are you ready to get your logistics costs under control? Give us a call at (866) 989-3082 or fill out a quote request online today!