Copy URL to Clipboard

Copy URL to Clipboard

One of the major decisions that business owners make when scaling up or down involves choosing warehouse solutions. More specifically, they need to decide whether their needs are better met through short term or long-term warehousing.

Key Takeaways:

This article will cover these points in greater detail and provide guidelines for selecting the right services and providers.

Warehousing, whether short or long-term, is used by companies to provide a means to secure their inventory before it heads out to the end user or the next step in the supply chain. However, each company’s unique needs will dictate which one is better, or even if a combination of both is needed.

Factors to consider include:

First, we’ll consider what’s meant by short-term warehousing.

Companies offering short-term warehousing generally provide month to month contracts for services. Occasionally, short-term contracts will be arranged in three-month intervals. Even leases that are less than a year can be arranged depending on the circumstances.

The most common service is basic storage, although some will also assist you with fulfillment solutions. When it comes to storage needs, you may hear a provider use the term on-demand warehousing.

Another form of short-term warehousing refers to fulfillment practices designed to limit the amount of time inventory is held. For instance, cross-docking services, where goods are unloaded from one truck and loaded onto another for final delivery. Depending on the nature of your business, this can be a long-term solution.

I’ll break this down into two parts to ensure we cover this fully. First, let’s consider when companies could benefit from month-to-month contacts for warehousing:

In each of these cases, the use of the warehouse space and related services is meant to be temporary. Even if it’s something done routinely, such as with seasonal merchandise.

A company with a long-term contract for most of their inventory needs can still utilize short-term warehousing as needed. Both play a part in successful inventory management.

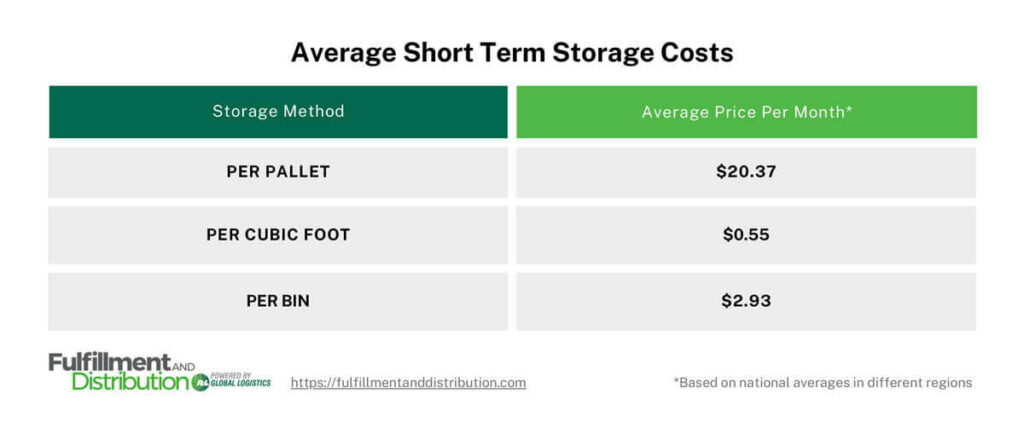

Realize that because of the month-to-month nature of most short-term contracts, your rates are likely to be higher. Costs vary between regions and by storage method, but I’ll keep it simple and focus on storage. Just understand that these are averages only, and you should always get exact pricing from potential warehouse providers.

Be sure to review your budget to ensure that you’re still able to profit from such an arrangement.

Now let’s look at who may benefit from short-term warehousing in terms of cross docking. Most businesses taking advantage of these services are B2B models that fulfill bulk or over-sized products.

For example, a company that deals in HVAC systems may deliver a full truckload of units to a warehouse for cross docking services that will then send products to companies that keep them in stock. This is referred to as hub and spoke distribution, and is often used to both improve delivery speed and save on extensive warehousing.

Related: What is the Hub and Spoke Distribution Model?

Entering into a long-term warehousing situation means having a permanent arrangement with a warehouse provider or third party logistics (3PL) company, usually with a one to three-year contract. Longer contracts are also possible, which also tends to improve the price of services.

Providers will often offer multiple types of services, from inventory management to kitting services. Ecommerce and B2B industries benefit from having a secure place for goods and a standardized system that can easily track inbound and outbound goods.

Related: 10 Reasons You Need to Outsource Inventory Management to a 3PL

Entering into a long-term contract with a 3PL, or other warehouse provider, is a big step towards scaling up your business. It also tends to be more financially viable than setting up a full warehousing system of your own.

Signs that you should be considering this option include:

The benefits of outsourcing your warehousing needs through a long-term contract go beyond cost savings, too. Many times you’ll gain access to better tracking tools, carrier rates, and trained personnel.

Because of the many services that 3PLs can provide long-term clients, determining average pricing is tough. There’s so much more involved than storage. Your best form of comparison is going to be when researching the difference between what the 3PLs services cost versus what it would cost if you were to start your own warehouse operation from the ground up.

Whether you’re shopping around for a long-term solution or just need warehousing for a few months, it’s still important to look for certain qualities in providers.

At Fulfillment and Distribution, we know all about the stress that comes with selecting a short term vs long-term warehousing solution. You want the best for your business and want to make sure your money is well spent.

Well, you’re in the right place. Our warehouse leadership has decades of combined experience in working with both B2B and direct retail clients. We also offer a long list of services, including short and long-term contracts at our professionally staffed warehouses.

Depending on what services you’re looking for, we can offer:

Our quality services will ensure your inventory and fulfillment needs are met to your expectations and then some. Call us today at (855) 989-3082 or get a direct service quote online.